0102030405

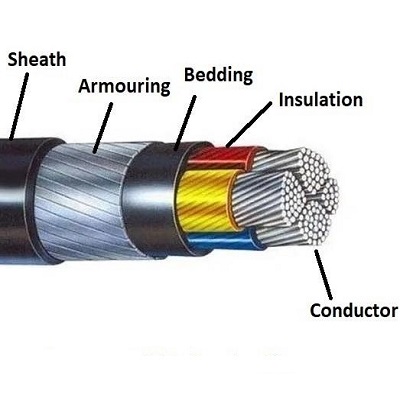

Why does the copper wire in the wire and cable blacken?

2024-08-09

- Drawing emulsion oil pool area is small, the return pipe is short and sealed, resulting in slow heat dissipation, leading to high emulsion oil temperature.

- It is caused by the annealing of copper wire. First, even pull even retreat cooling water is generally used tap water, groundwater, due to the water quality is not the same everywhere, some areas of the water quality of the PH value is low, only 5.5 ~ 5.0 (normal is 7.0 ~ 7.5), the original emulsion in the antioxidant film are cleaned off, the annealing of the copper wire is easy to oxidation, blackening; Second, in the ordinary wire drawing machine pull good finished copper wire annealed on the other annealing line, the cooling water also No use of antioxidants, antioxidant time is short, will soon appear oxidation and blackening phenomenon.

- Some old factories still use annealing cylinder to anneal, the following reasons will also cause oxidation, blackening: First, the annealing cylinder nut is not tightened, after punching carbon dioxide or high-purity nitrogen leakage; Second, the copper wire out of the cylinder is too high a temperature, exceeding 30 ℃; Third, the wire drawing emulsion maintenance is not enough, the PH value is too low; These cases are more common in summer when the temperature is high, the emulsion will be used non-stop depletion, the temperature is high, then depletion Faster, if not timely replenishment of new crude oil, which contains very little fat, coupled with high temperatures, the temperature of the emulsion may also exceed 45 ℃, it is easy to cause oxidation and blackening.

- Another situation is that, due to the current widespread use of high-speed drawing, its speed increased, the relative heat dissipation time is reduced, to the oxidation of a certain amount of space and time, therefore, it is recommended that manufacturers pay more attention to the emulsion of the fat content of the situation, the use of temperature, PH value, etc. Whether it is appropriate to use the yellow mould and rain season in the spring, the bacterial reproduction of the faster, can be used in the bactericidal mildew agent, the summer can be used as an antioxidant to solve the oxidation, the blackening of the problem! It will not be a problem.

Solution:

Add a rubber pad in the direction of the outlet of the finished mould, and then thread the finished mould to solve the problem of oil leakage.

Finished mould deformation is small, is a common mistake, single mould deformation need to have a small amount of deformation, the resulting pressure may be greater than the yield limit of the metal, can be achieved is plastic deformation, the size can be stable, the surface of the single line will have a cold pulling produced by the light.