Type Test VS Certification

Do you know the difference between type testing and product certification? Maybe the confusion in the market can lead to the wrong choice, and this guide will clarify the difference between the two to help you choose the right product.

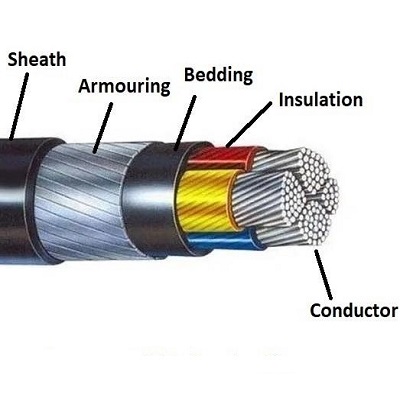

The structure of the cable is complex, according to the function and application requirements of the cable, there are multiple layers of metal and non-metal materials, and the thickness and manufacturing process are different.

The materials used in the cable layer all have unique properties, such as insulation, cushions, jackets, fillers, tapes, shields, coatings, etc., which must be consistently achieved through a tightly controlled manufacturing process.

Cable applications and performance are routinely verified by manufacturers and end users, and suitability can be verified by independent bodies through testing and certification.

Third Party Type Testing or One-Off Testing

Typically cable testing may be a comprehensive type test according to the design criteria of a specific cable type (such as BS 5467, BS 6724, etc.). It may also be just one of the specific tests for a specific cable type (such as the halogen content test for IEC 60754-1 or the smoke emission test for IEC 61034-2 and other LSZH cables). Considerations for "one-time" testing by a third party include the following:

- Cable type tests are performed on only one cable size/sample for a specific cable type/construction or voltage class.

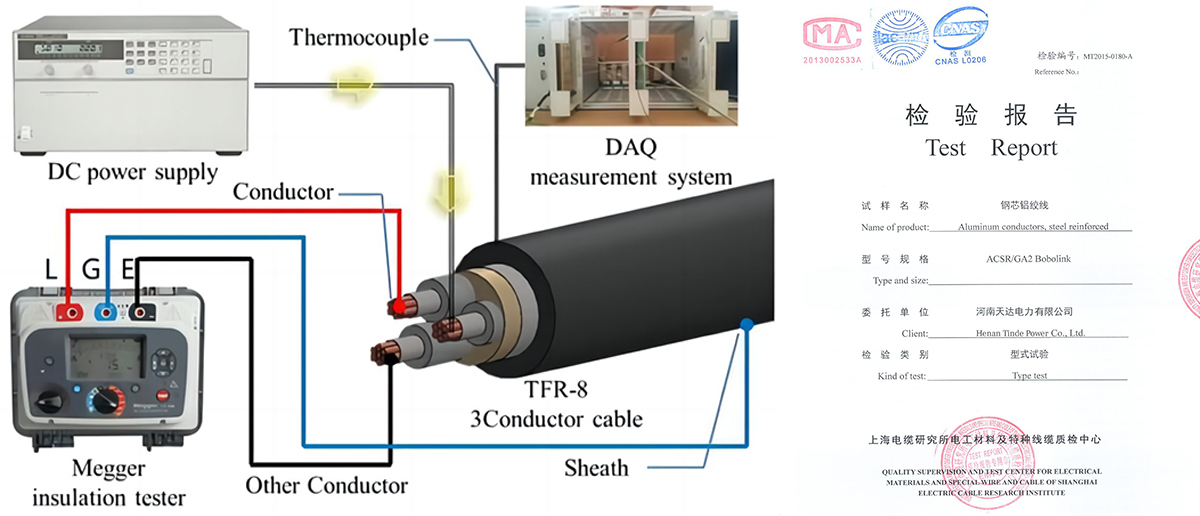

- Cable manufacturers prepare samples at the factory, test them in-house, and then send them to third-party laboratories for testing.

- Third parties are not involved in the selection of samples, leading to the suspicion that only good or "gold samples" are tested.

- After passing the test, the third party will issue the type test report.

- The type test report covers only the sample tested. Type test reports refer only to tested samples and cannot be used to claim that untested samples meet standards or specifications.

- Such tests are generally not repeated for 5-10 years unless requested by the customer or the authority/utility.

Type testing is therefore a microcosm of time and does not allow continuous assessment of cable quality or changes in manufacturing processes or raw materials through routine testing and/or production monitoring.

Third-Party Certification for Cables

Certification goes further than type testing and involves an audit of the cable manufacturing plant and, in some cases, an annual cable sampling test.

The key points of third-party authentication are as follows:

- Certification is always for the cable product line (including all cable sizes/cores)

- Involves factory audits and, in some cases, annual cable testing.

- Certificates are usually valid for 3 years, but will be reissued when routine audits and tests confirm continued compliance.

- Compared to type testing, it has the advantage of continuous monitoring of production through audits and tests in some cases.