Hard drawn copper wire VS Annealed copper wire

Copper wire is a widely used in electrical, the following mainly discusses the difference between hard drawn copper and annealed copper:

Annealed copper is obtained through a heat treatment process, which is a process of slowly heating the metal to a certain temperature, keeping it for a sufficient time, and then cooling it at an appropriate rate. This treatment method can improve the internal structure of the metal, reduce the hardness, and increase the plasticity, so as to facilitate processing and forming. Annealed copper is usually used in applications that require better plasticity, such as making products that need to be bent or formed.

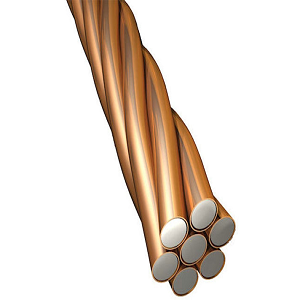

Hard drawn copper is obtained by cold working, that is, copper is processed by stretching or extrusion. This processing method increases the strength and hardness of the metal, but may reduce its plasticity and toughness. Hard drawn copper is usually used in applications that require higher strength and wear resistance because it can provide better mechanical properties.

In general, the main difference between annealed copper and hard drawn copper lies in their physical properties and uses. Annealed copper is mainly used in applications that require better plasticity, such as products that need to be bent or formed; while hard drawn copper is used in applications that require higher strength and wear resistance. These two treatment methods have their own advantages and are suitable for different industrial and process requirements.

Henan Tinde Power Cable delivers more than just wire and cable products. We’re also with capabilities tailored for our customer’s needs, help to design a cable to make your vision a reality. For more information on our capabilities and product lines, please contact us or submit a quote request.