IEC/BS Standard XLPE Insulated LV Power Cable

Application

XLPE insulated power cables find widespread use in various sectors, including: Utility Grids: High-voltage transmission lines, underground distribution networks, and substation connections. Industrial Installations: Power supply for factories, processing plants, and heavy machinery. Infrastructure Projects: Railways, airports, tunnels, bridges, and urban transportation systems. Commercial Buildings: Main power supply, emergency backup systems, and data centers.

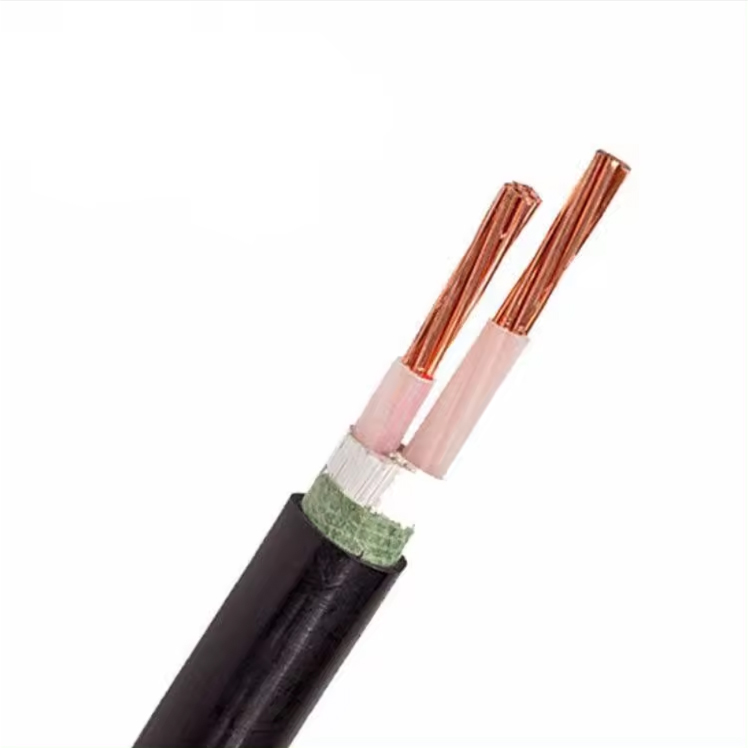

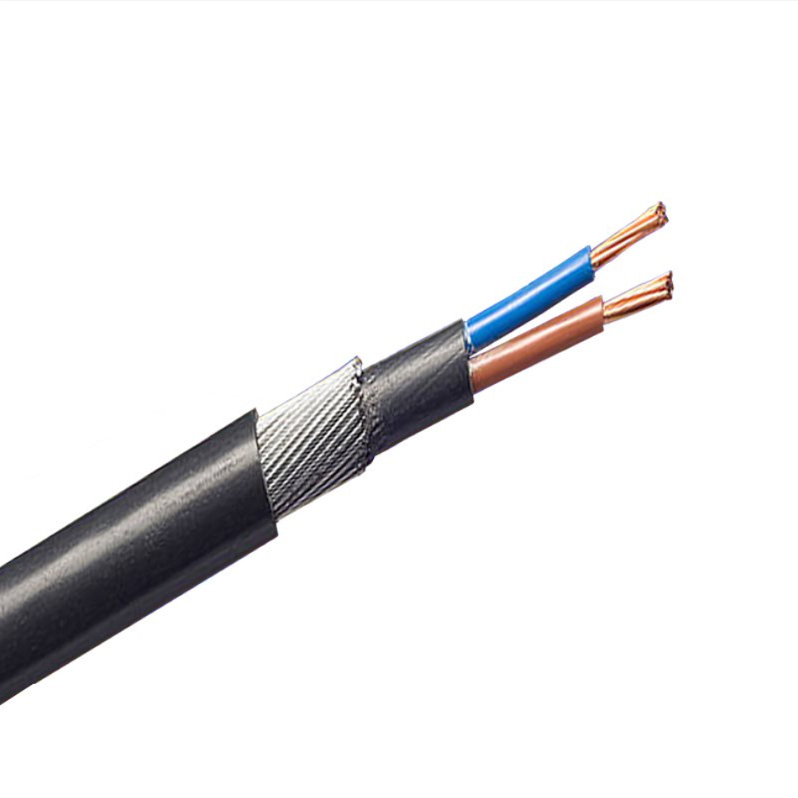

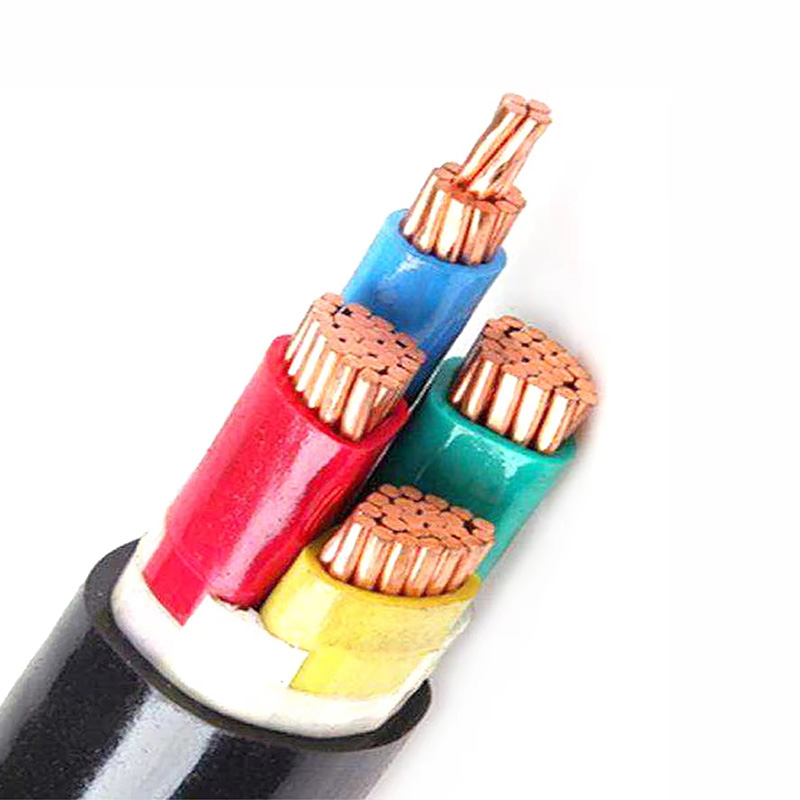

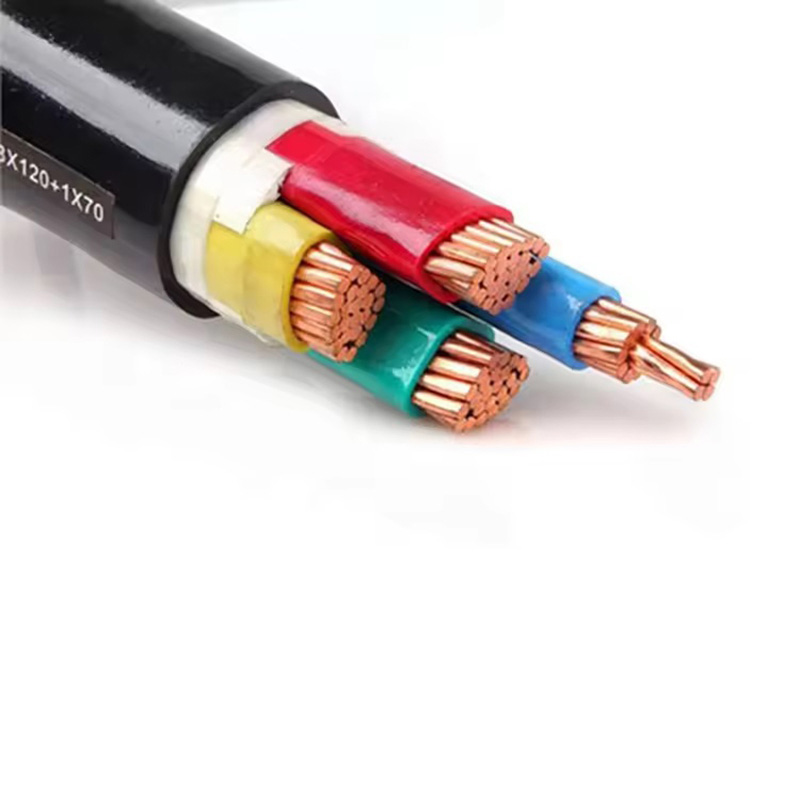

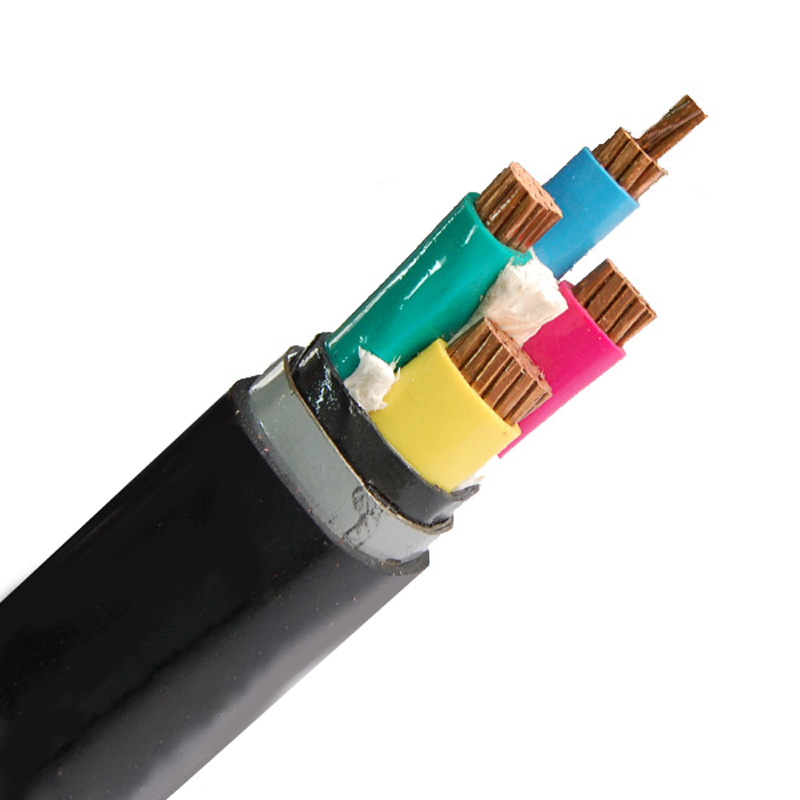

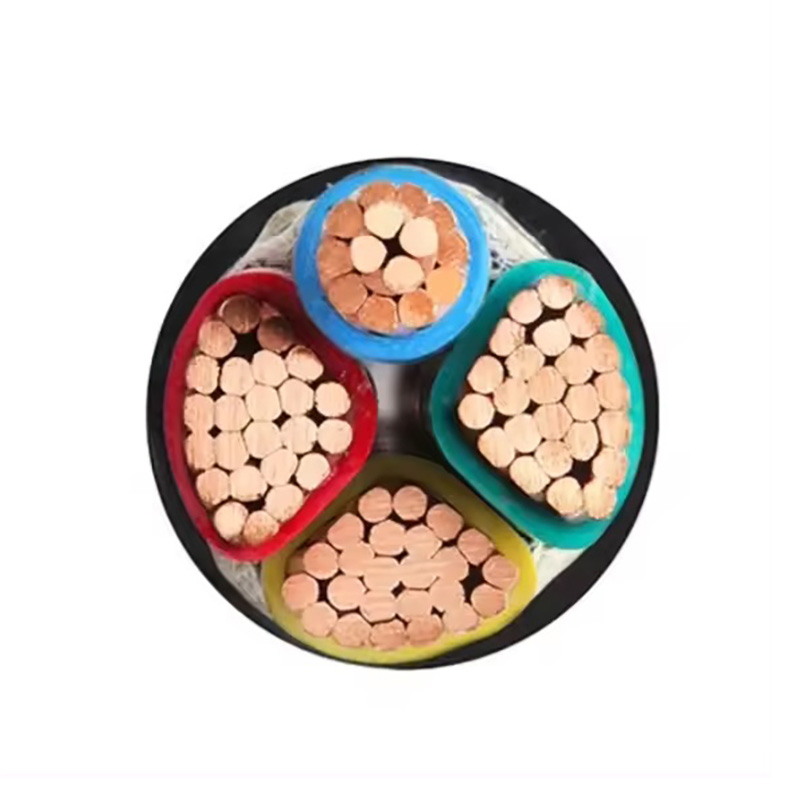

Construction

Conductor: Class 2 stranded copper conductor or aluminium conductor

Insulation: XLPE

Armour method: Unarmored or Steel Wire Armour (SWA), Steel Tape Armour (STA), Aluminium Wire Armour (AWA), Aluminium Tape Armour (ATA)

Outer sheath: PVC (polyvinyl chloride), or rodent and termite-resistant PVC (optional)

Characteristics

| Rated voltage | 600/1000V |

| Rated temperature | 0°C to +90°C |

| Bending radius | 1.5mm² to 16mm²: 6 x outer diameter |

| 25mm² and above | 8 x outer diameter |

| Fire resistance | IEC 60332 Part 1, BS4066 Part 1 |

Core color

1. core: brown2. cores: brown, blue3. cores: brown, black and grey4. cores: brown, black, gray and blue5. cores: brown, black, gray, blue and green/yellow

600/1000 V-Two core copper conductor xlpe insulated swa pvc sheathed cables

Data Sheet

600/1000 V-Two core copper conductor xlpe insulated swa pvc sheathed cables (CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of extruded bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight |

| mm2 | Ohm/km | mm | mm | mm | mm | mm | kg/km |

| 1.5* | 12.1 | 0.7 | 1 | 0.9 | 1.8 | 14.2 | 355 |

| 1.5 | 12.1 | 0.7 | 1 | 0.9 | 1.8 | 14.6 | 370 |

| 2.5* | 7.41 | 0.7 | 1 | 0.9 | 1.8 | 15 | 400 |

| 2.5 | 7.41 | 0.7 | 1 | 0.9 | 1.8 | 15.4 | 415 |

| 4 | 4.61 | 0.7 | 1 | 0.9 | 1.8 | 16.4 | 480 |

| 6 | 3.08 | 0.7 | 1 | 0.9 | 1.8 | 17.6 | 570 |

| 10 | 1.83 | 0.7 | 1 | 1.25 | 1.8 | 20.3 | 820 |

| 16 | 1.15 | 0.7 | 1 | 1.25 | 1.8 | 22.3 | 1030 |

| 25 | 0.727 | 0.9 | 1 | 1.6 | 1.8 | 26.3 | 1530 |

| 35 | 0.524 | 0.9 | 1 | 1.6 | 1.8 | 28.5 | 1840 |

| 50 | 0.387 | 1 | 1 | 1.6 | 1.8 | 30.9 | 2070 |

| 70 | 0.268 | 1.1 | 1 | 1.6 | 2 | 34.9 | 2670 |

| 95 | 0.193 | 1.1 | 1.2 | 2 | 2.1 | 40.1 | 3660 |

| 120 | 0.153 | 1.2 | 1.2 | 2 | 2.2 | 43.7 | 4350 |

| 150 | 0.124 | 1.4 | 1.2 | 2 | 2.3 | 47.5 | 5160 |

| 185 | 0.0991 | 1.6 | 1.4 | 2.5 | 2.5 | 53.3 | 6600 |

| 240 | 0.0754 | 1.7 | 1.4 | 2.5 | 2.7 | 59.1 | 8100 |

| 300 | 0.0601 | 1.8 | 1.6 | 2.5 | 2.8 | 64.1 | 9660 |

| 400 | 0.047 | 2 | 1.6 | 2.5 | 3.1 | 71.3 | 12000 |

| 500 | 0.0366 | 2.2 | 1.6 | 3.15 | 3.3 | 79.8 | 15500 |

* Circular solid conductors (Class 1).All other conductors Circular stranded or circular stranded compacted (Class 2).Cables conform to BS 5467 and generally to IEC 60502 – 1.

600/1000V-Three core copper conductor xlpe insulated swa pvc sheathed cables (CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight | |||

| Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | |||||

| mm2 | Ohm/km | mm | mm | mm | mm | mm | kg/km | |||

| 1.5* | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.3 | – | 330 | – |

| 1.5 | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.7 | – | 350 | – |

| 2.5* | 7.41 | 0.7 | 0.8 | – | 0.9 | 1.4 | 14.4 | – | 390 | – |

| 2.5 | 7.41 | 0.7 | 0.8 | 0.9 | 1.4 | 14.8 | – | 415 | – | |

| 4 | 4.61 | 0.7 | 0.8 | – | 0.9 | 1.4 | 15.9 | – | 490 | – |

| 6 | 3.08 | 0.7 | 0.8 | – | 0.9 | 1.4 | 17.2 | – | 580 | – |

| 10 | 1.83 | 0.7 | 0.8 | – | 1.25 | 1.5 | 19.6 | – | 850 | – |

| 16 | 1.15 | 0.7 | 0.8 | – | 1.25 | 1.6 | 22.2 | – | 1110 | – |

| 25 | 0.727 | 0.9 | 1 | 0.8 | 1.6 | 1.7 | 24.3 | 23.2 | 1520 | 1420 |

| 35 | 0.524 | 0.9 | 1 | 0.8 | 1.6 | 1.8 | 26.9 | 25.8 | 1910 | 1790 |

| 50 | 0.387 | 1 | 1 | 0.8 | 1.6 | 1.8 | 30.1 | 29 | 2400 | 2250 |

| 70 | 0.268 | 1.1 | 1 | 0.8 | 1.6 | 1.9 | 32.8 | 31.7 | 3100 | 2950 |

| 95 | 0.193 | 1.1 | 1.2 | 0.8 | 2 | 2.1 | 38.2 | 36.7 | 4310 | 4060 |

| 120 | 0.153 | 1.2 | 1.2 | 0.8 | 2 | 2.2 | 41.8 | 40.3 | 5170 | 4920 |

| 150 | 0.124 | 1.4 | 1.4 | 0.8 | 2.5 | 2.3 | 46.4 | 44.5 | 6620 | 6290 |

| 185 | 0.0991 | 1.6 | 1.4 | 0.8 | 2.5 | 2.4 | 50.8 | 48.9 | 7860 | 7510 |

| 240 | 0.0754 | 1.7 | 1.4 | 0.8 | 2.5 | 2.6 | 56.9 | 55 | 9810 | 9410 |

| 300 | 0.0601 | 1.8 | 1.6 | 0.8 | 2.5 | 2.7 | 61.8 | 59.5 | 11910 | 11430 |

| 400 | 0.047 | 2 | 1.6 | 0.8 | 2.5 | 2.9 | 69.2 | 66.9 | 14910 | 14330 |

* Circular solid conductors (Class 1).Conductors including 16sqmm circular stranded (Class 2).25sqmm and above shaped stranded conductors(Class 2).Cables conform to BS 5467 and generally to IEC 60502-1.

600/1000V-Four core copper conductor xlpe insulated pvc sheathed cables(CU/XLPE/PVC/SWA/PVC)

| Nominal area of conductor | Maximum conductor resistance at 20°c | Thickness of insulation | Thickness of bedding | Dia. Of armour wire | Thickness of outer sheath | Approx.overall diameter | Approx.cable weight | |||

| Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | Extruded bedding | Lapped bedding | |||||

| mm2 | Ohm/km | mm | mm | mm | mm | mm | kg/km | |||

| 1.5* | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.3 | – | 330 | – |

| 1.5 | 12.1 | 0.7 | 0.8 | – | 0.9 | 1.3 | 13.7 | – | 350 | – |

| 2.5* | 7.41 | 0.7 | 0.8 | – | 0.9 | 1.4 | 14.4 | – | 390 | – |

| 2.5 | 7.41 | 0.7 | 0.8 | 0.9 | 1.4 | 14.8 | – | 415 | – | |

| 4 | 4.61 | 0.7 | 0.8 | – | 0.9 | 1.4 | 15.9 | – | 490 | – |

| 6 | 3.08 | 0.7 | 0.8 | – | 0.9 | 1.4 | 17.2 | – | 580 | – |

| 10 | 1.83 | 0.7 | 0.8 | – | 1.25 | 1.5 | 19.6 | – | 850 | – |

| 16 | 1.15 | 0.7 | 0.8 | – | 1.25 | 1.6 | 22.2 | – | 1110 | – |

| 25 | 0.727 | 0.9 | 1 | 0.8 | 1.6 | 1.7 | 24.3 | 23.2 | 1520 | 1420 |

| 35 | 0.524 | 0.9 | 1 | 0.8 | 1.6 | 1.8 | 26.9 | 25.8 | 1910 | 1790 |

| 50 | 0.387 | 1 | 1 | 0.8 | 1.6 | 1.8 | 30.1 | 29 | 2400 | 2250 |

| 70 | 0.268 | 1.1 | 1 | 0.8 | 1.6 | 1.9 | 32.8 | 31.7 | 3100 | 2950 |

| 95 | 0.193 | 1.1 | 1.2 | 0.8 | 2 | 2.1 | 38.2 | 36.7 | 4310 | 4060 |

| 120 | 0.153 | 1.2 | 1.2 | 0.8 | 2 | 2.2 | 41.8 | 40.3 | 5170 | 4920 |

| 150 | 0.124 | 1.4 | 1.4 | 0.8 | 2.5 | 2.3 | 46.4 | 44.5 | 6620 | 6290 |

| 185 | 0.0991 | 1.6 | 1.4 | 0.8 | 2.5 | 2.4 | 50.8 | 48.9 | 7860 | 7510 |

| 240 | 0.0754 | 1.7 | 1.4 | 0.8 | 2.5 | 2.6 | 56.9 | 55 | 9810 | 9410 |

| 300 | 0.0601 | 1.8 | 1.6 | 0.8 | 2.5 | 2.7 | 61.8 | 59.5 | 11910 | 11430 |

| 400 | 0.047 | 2 | 1.6 | 0.8 | 2.5 | 2.9 | 69.2 | 66.9 | 14910 | 14330 |

* All conductors shaped stranded(Class 2)Cables conform to IEC 60502-1Drum size given above are for cables with extruded bedding