IEC/BS Standard 3.8/6.6kV XLPE Insulated MV Middle Voltage Power Cable

Application

Suitable for energy networks such as power plants and distribution system etc. Typically used for installation in ducts, underground and outdoors.

Due to its robustness and high electrical stability, medium voltage cables are used in harsh environments.

Note: Red outer sheath can be prone to fading when exposed to UV rays.

Standards

Flame propagation to BS EN60332BS6622IEC 60502

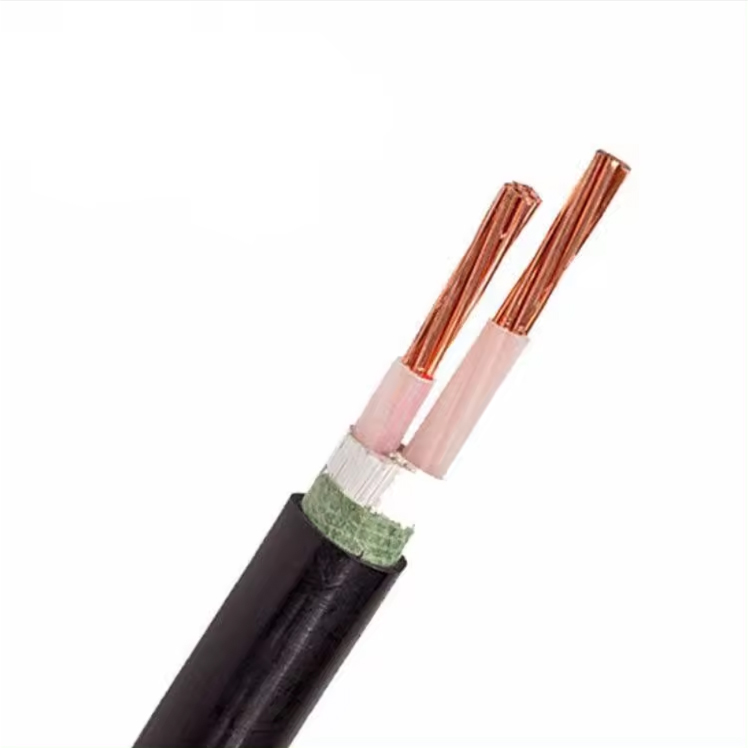

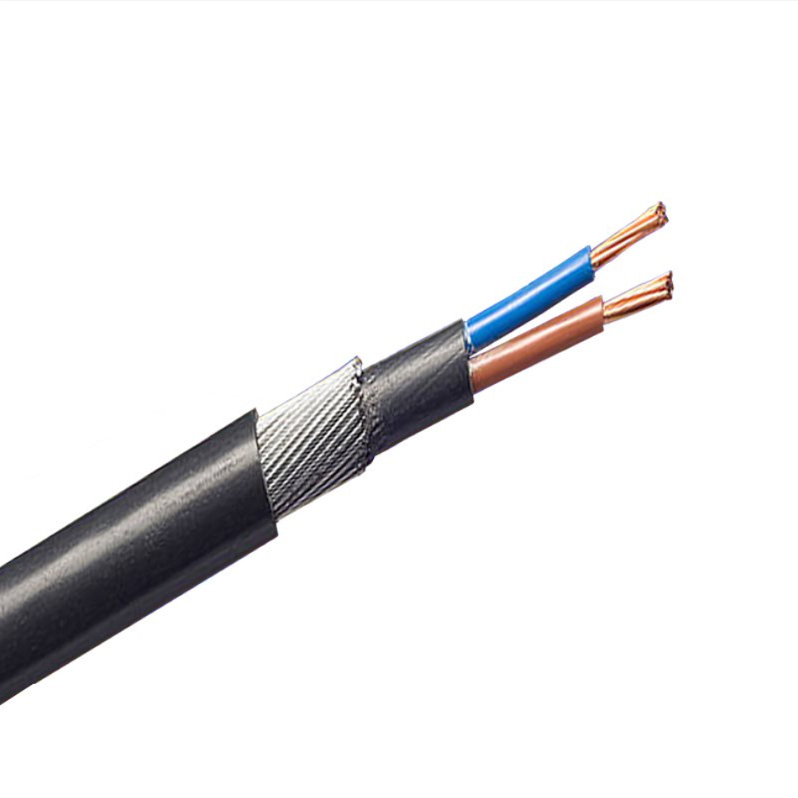

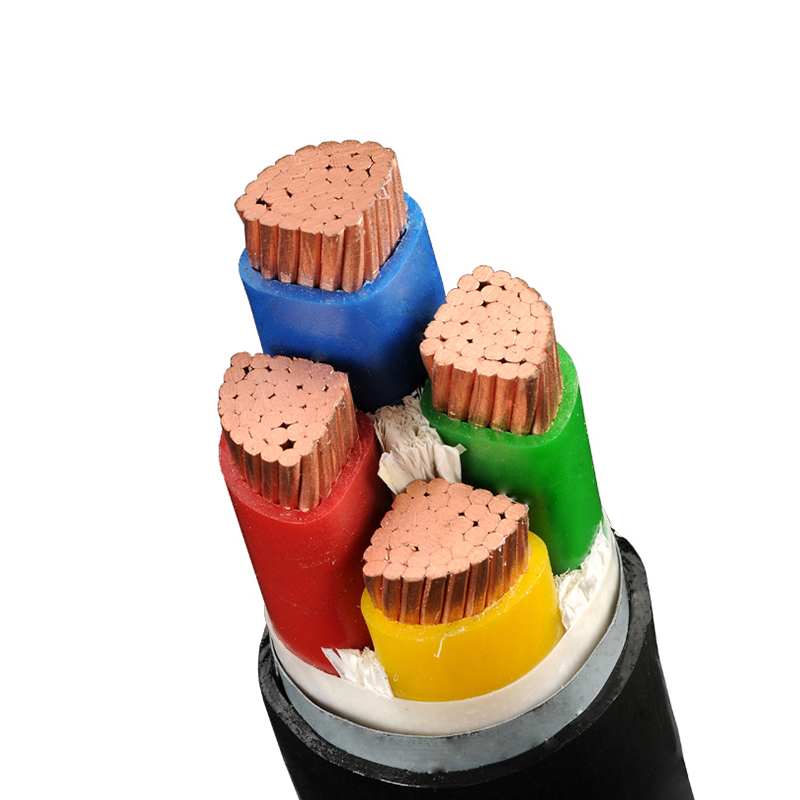

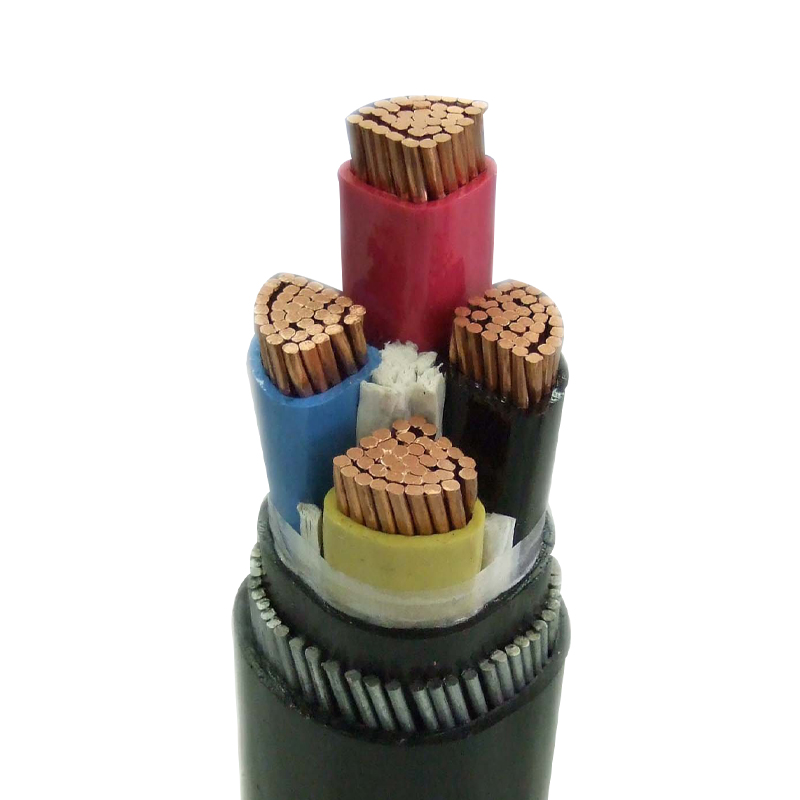

Cable Construction

Conductor: stranded plain annealed circular compacted copper conductors or aluminium conductor

Insulated: cross link polyethylene (XLPE)

Metallic Screen: individual or overall copper tape shielding

Isolation layer: copper tape with an overlap of 10%

Bedding: polyvinyl chloride (PVC)

Armoured: Steel Wire Armour (SWA), Steel Tape Armour (STA), Aluminium Wire Armour (AWA), Aluminium Tape Armour (ATA)

Sheath: PVC/PE outer sheath

Sheath colour: Red / Black

Electrical data

Conductor max operating temperature: 90°C

Screen max operating temperature: 80°C

Conductor max temperature during S.C: 250°C

Laying conditions at trefoil formation

Soil thermal resistivity: 120˚C. Cm/Watt

Burial depth: 0.5m

Ground temperature: 15°C

Air temperature: 25°C

Frequency: 50Hz

Data Sheet

3.8/6.6kV-Single core copper/cu conductor xlpe insulated copper tape screened aluminium wire armoured pvc sheathed cables

|

Nominal area of conductor |

Maximum conductor resistance at 20 ℃ |

Thickness of xlpe insulation |

Thickness of copper tape |

Thickness of extruded bedding |

Dia of armoured wire |

Thickness of outer sheath |

Approx. Overall diameter |

Approx. Cable weight |

|

mm2 |

Ω/km |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

|

35 |

0.524 |

2.5 |

0.075 |

1.2 |

1.6 |

1.8 |

25.5 |

1020 |

|

50 |

0.387 |

2.5 |

0.075 |

1.2 |

1.6 |

1.8 |

26.6 |

1180 |

|

70 |

0.268 |

2.5 |

0.075 |

1.2 |

1.6 |

1.8 |

28.2 |

1440 |

|

95 |

0.193 |

2.5 |

0.075 |

1.2 |

1.6 |

1.9 |

30.3 |

1760 |

|

120 |

0.153 |

2.5 |

0.075 |

1.2 |

1.6 |

1.9 |

31.8 |

2050 |

|

150 |

0.124 |

2.5 |

0.075 |

1.2 |

1.6 |

2 |

33.4 |

2380 |

|

185 |

0.0991 |

2.5 |

0.075 |

1.2 |

2 |

2 |

35.8 |

2840 |

|

240 |

0.0754 |

2.6 |

0.075 |

1.2 |

2 |

2.1 |

38.7 |

3490 |

|

300 |

0.0601 |

2.8 |

0.075 |

1.2 |

2 |

2.2 |

41.3 |

4180 |

|

400 |

0.047 |

3 |

0.075 |

1.2 |

2 |

2.3 |

44.8 |

5160 |

|

500 |

0.0366 |

3.2 |

0.075 |

1.3 |

2.5 |

2.5 |

49.8 |

6490 |

|

630 |

0.0283 |

3.2 |

0.075 |

1.4 |

2.5 |

2.6 |

54 |

8020 |

3.8/6.6kV-Three cores copper conductor xlpe insulated copper tape screened galvanized steel wire armoured pvc/pe sheathed cables

| Nominal area of conductor | Maximum conductor resistance at 20 ℃ | Thickness of xlpe insulation | Thickness of copper tape | Thickness of extruded bedding | Dia of armoured wire | Thickness of outer sheath | Approx. Overall diameter | Approx. Cable weight |

|

mm2 |

Ω/km |

mm |

mm |

mm |

mm |

mm |

kg/km |

|

|

35 |

0.524 |

3.4 |

0.075 |

1.2 |

1.6 |

1.8 |

27.3 |

1130 |

|

50 |

0.387 |

3.4 |

0.075 |

1.2 |

1.6 |

1.8 |

28.4 |

1290 |

|

70 |

0.268 |

3.4 |

0.075 |

1.2 |

1.6 |

1.9 |

30.2 |

1560 |

|

95 |

0.193 |

3.4 |

0.075 |

1.2 |

1.6 |

1.9 |

32.1 |

1880 |

|

120 |

0.153 |

3.4 |

0.075 |

1.2 |

1.6 |

2 |

33.8 |

2190 |

|

150 |

0.124 |

3.4 |

0.075 |

1.2 |

2 |

2.1 |

36.2 |

2620 |

|

185 |

0.0991 |

3.4 |

0.075 |

1.2 |

2 |

2.1 |

37.8 |

3000 |

|

240 |

0.0754 |

3.4 |

0.075 |

1.2 |

2 |

2.2 |

40.5 |

3640 |

|

300 |

0.0601 |

3.4 |

0.075 |

1.2 |

2 |

2.2 |

42.5 |

4290 |

|

400 |

0.047 |

3.4 |

0.075 |

1.2 |

2 |

2.4 |

45.8 |

5270 |

|

500 |

0.0366 |

3.4 |

0.075 |

1.3 |

2.5 |

2.5 |

50.2 |

6550 |

|

630 |

0.0283 |

3.4 |

0.075 |

1.4 |

2.5 |

2.6 |

54.4 |

8020 |