ASTM UL XLPE XHHW XHHW-2 Copper Wire High Heat-resistant Water-resistant

Application

XHHW XHHW-2 Copper Wire is commonly used in residential, commercial and industrial buildings and installations for the purpose of power distribution,conduit or other recognized raceways for services, feeders, and branch circuit wiring both copper and aluminum conductors,wet and dry condition.

Technical Performance

| Rated Voltage (Uo/U) | 600V |

| Conductor temperature | Maximum conductor temperature in normal use: 250ºC |

| Installation temperature | Ambient temperature under installation shall not be below -40ºC |

| Minimum bending radius | |

| The bending radius of cable | 4 x cable diameter |

Constructions

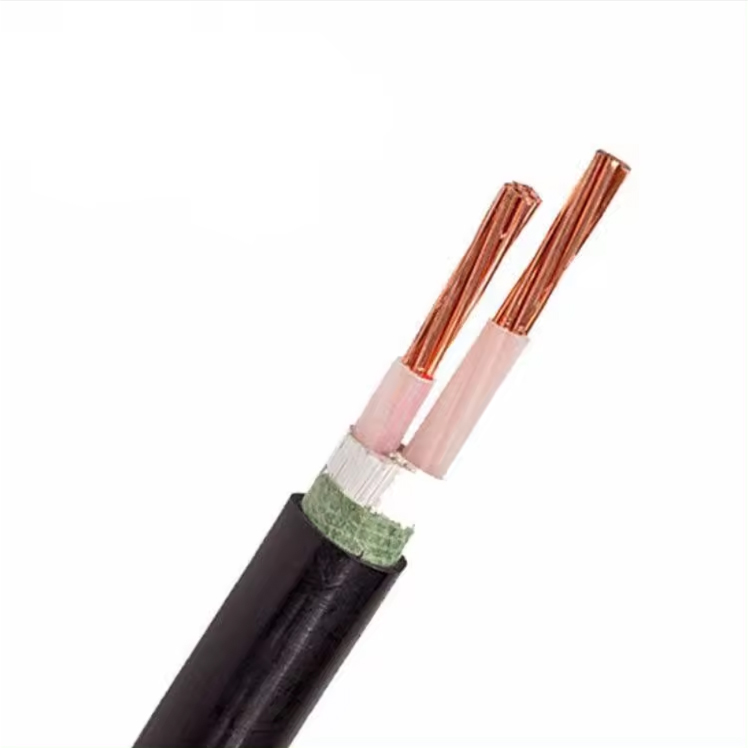

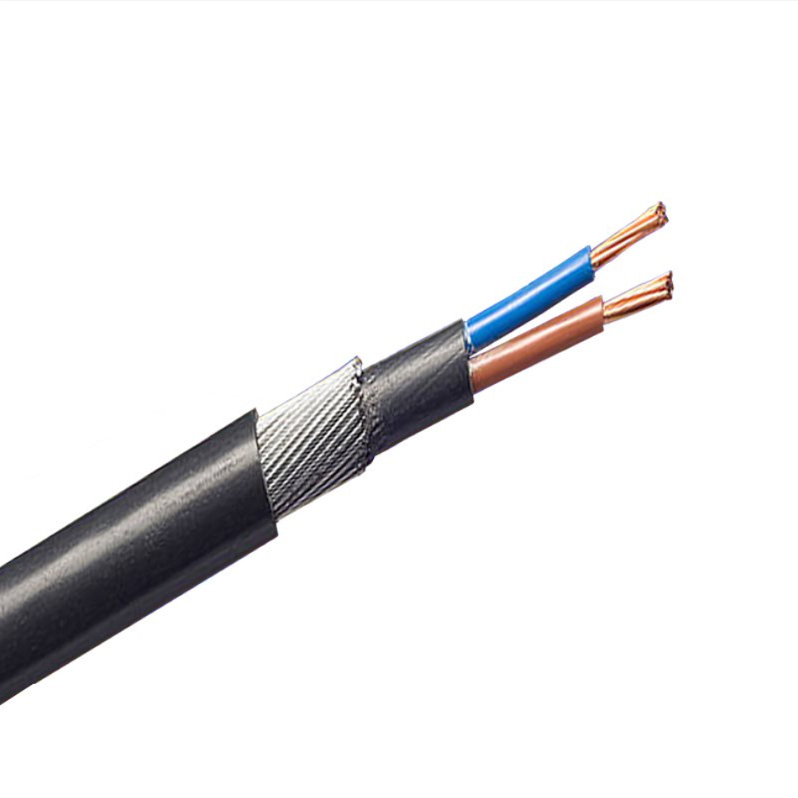

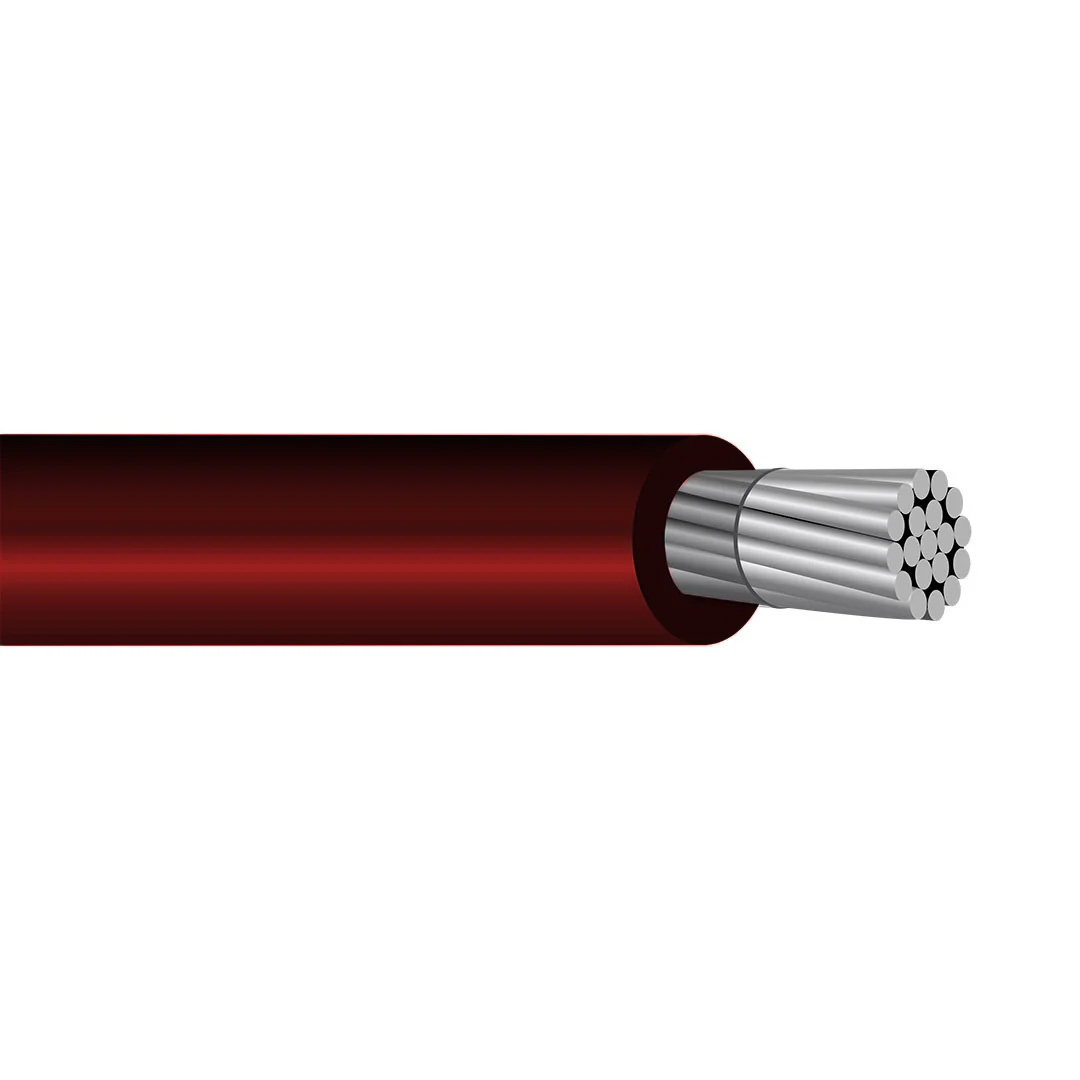

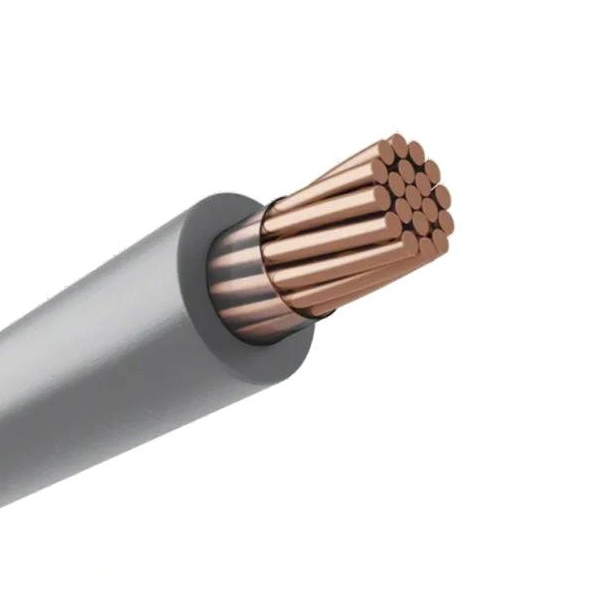

Conductor: solid/multi-strand annealed copper

Insulation: cross-linked polyethylene (XLPE)

Color: Black, gray, other colors

Specifications

ASTM B3, B8UL 1581 - Flame exposure testUL 44 - Thermoplastic material insulated cable

Data Sheet

|

Size |

No.OF WIRES |

Insulation Thickness |

Nominal overall diameter |

Nominal Weight |

|||

|

AWG |

No. |

INCH / MM |

INCH / MM |

LBS/KFT KG/KM |

|||

|

14 |

1 |

0.03 |

0.76 |

0.124 |

3.15 |

16 |

24 |

|

12 |

1 |

0.03 |

0.76 |

0.141 |

3.58 |

24 |

36 |

|

10 |

1 |

0.03 |

0.76 |

0.162 |

4.11 |

37 |

55 |

|

8 |

1 |

0.045 |

1.14 |

0.218 |

5.55 |

61 |

91 |

|

6 |

1 |

0.045 |

1.14 |

0.252 |

6.4 |

93 |

138 |

|

14 |

7 |

0.03 |

0.76 |

0.133 |

3.37 |

17 |

26 |

|

12 |

7 |

0.03 |

0.76 |

0.152 |

3.85 |

26 |

39 |

|

10 |

7 |

0.03 |

0.76 |

0.176 |

4.46 |

39 |

58 |

|

8 |

7 |

0.045 |

1.14 |

0.236 |

5.99 |

65 |

96 |

|

6 |

7 |

0.045 |

1.14 |

0.274 |

6.95 |

98 |

146 |

|

4 |

19 |

0.045 |

1.14 |

0.316 |

8.04 |

148 |

220 |

|

3 |

19 |

0.045 |

1.14 |

0.344 |

8.75 |

184 |

274 |

|

2 |

19 |

0.045 |

1.14 |

0.376 |

9.54 |

229 |

341 |

|

1 |

19 |

0.045 |

1.14 |

0.431 |

10.94 |

292 |

434 |

|

1/0 |

19 |

0.055 |

1.4 |

0.47 |

11.94 |

364 |

541 |

|

2/0 |

19 |

0.055 |

1.4 |

0.514 |

13.07 |

453 |

674 |

|

3/0 |

19 |

0.055 |

1.4 |

0.564 |

14.33 |

566 |

842 |

|

4/0 |

19 |

0.055 |

1.4 |

0.62 |

15.75 |

708 |

1053 |

|

250 |

37 |

0.065 |

1.65 |

0.706 |

17.93 |

838 |

1247 |

|

300 |

37 |

0.065 |

1.65 |

0.761 |

19.33 |

999 |

1486 |

|

350 |

37 |

0.065 |

1.65 |

0.812 |

20.62 |

1159 |

1725 |

|

400 |

37 |

0.065 |

1.65 |

0.859 |

21.82 |

1319 |

1963 |

|

500 |

37 |

0.065 |

1.65 |

0.945 |

24 |

1639 |

2439 |

|

600 |

61 |

0.08 |

2.03 |

1.053 |

26.75 |

1980 |

2946 |

|

750 |

61 |

0.08 |

2.03 |

1.159 |

29.44 |

2459 |

3660 |

|

1000 |

61 |

0.08 |

2.03 |

1.313 |

33.35 |

3256 |

4845 |