ASTM UL Thermoplastic Wire Type TW/THW THW-2 Cable

Application

TW/THW wire is most often used in general purpose wiring circuits, for machine tool wiring and the internal wiring of appliances. Common applications include building wiring, feeder and branch circuits, and internal secondary industrial distribution control panels, wiring for refrigeration equipment, air-conditioning equipment, control wiring of machine tools, automatic washers, etc.

Technical Performance

| Rated Voltage (Uo/U) | 600V |

| Conductor temperature | Maximum conductor temperature in normal use: 250ºC |

| Installation temperature | Ambient temperature under installation shall not be below -40ºC |

| Minimum bending radius | |

| The bending radius of cable | 4 x cable diameter |

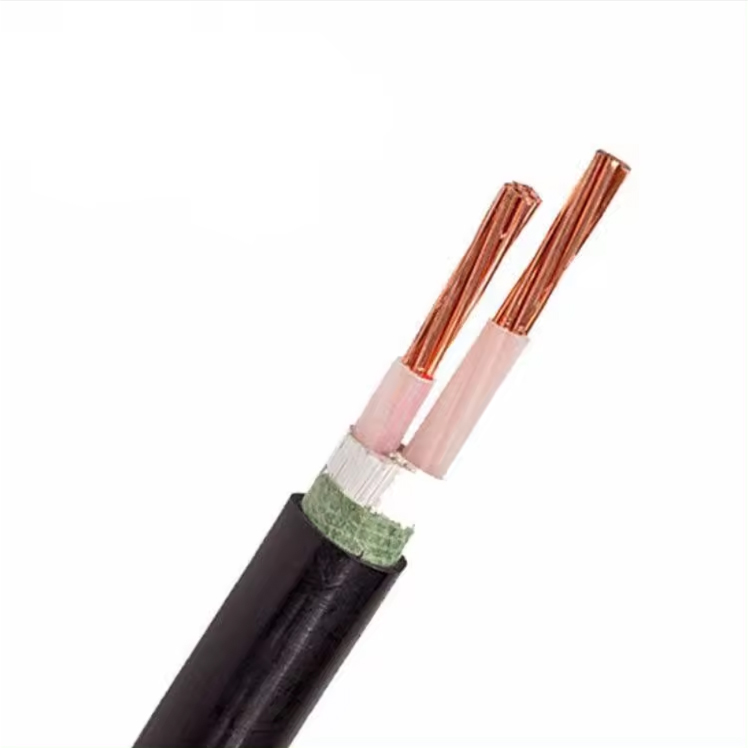

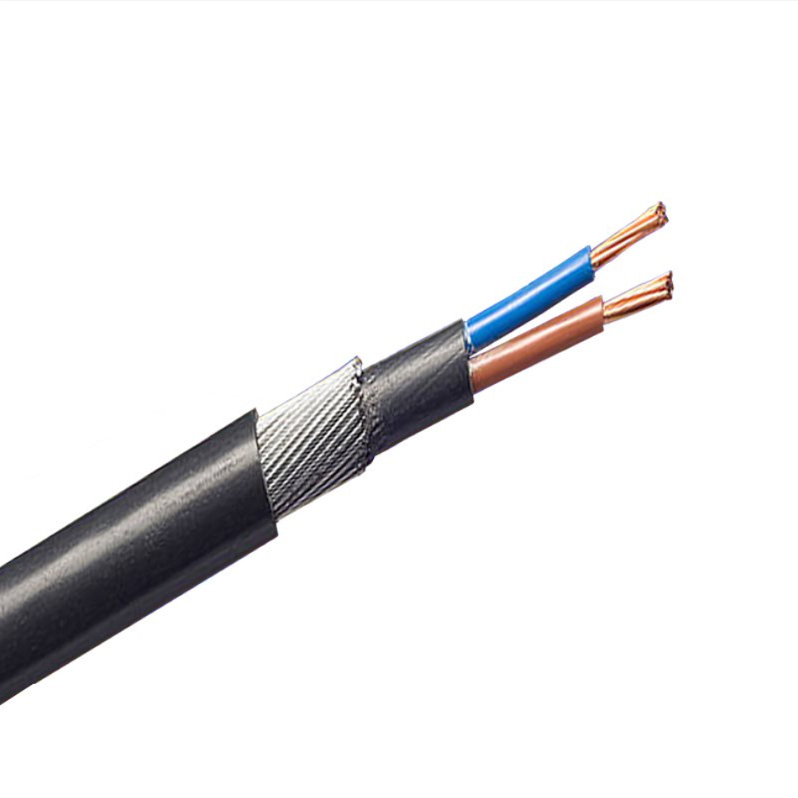

Constructions

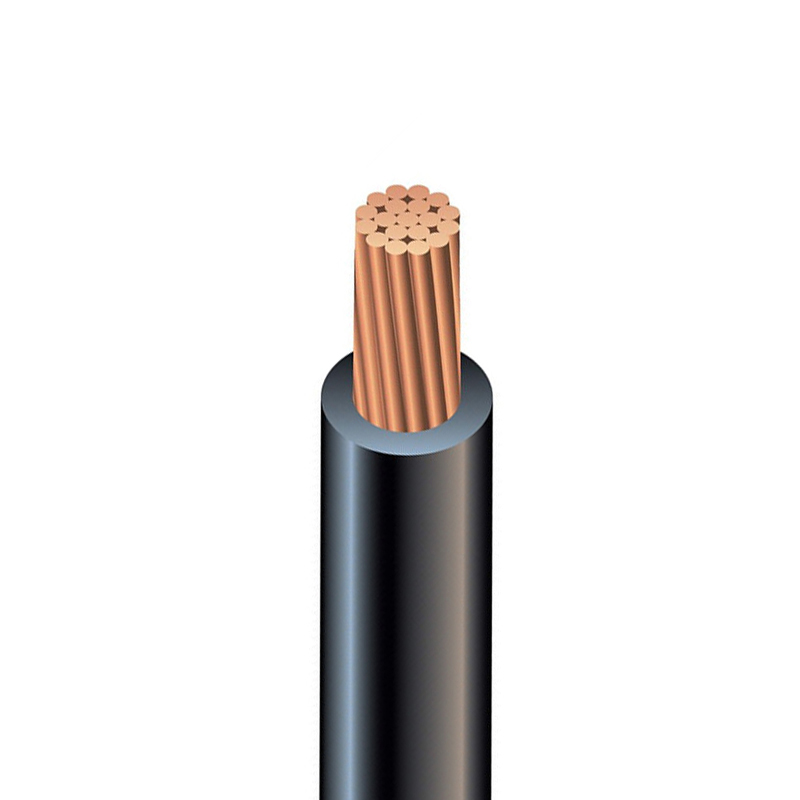

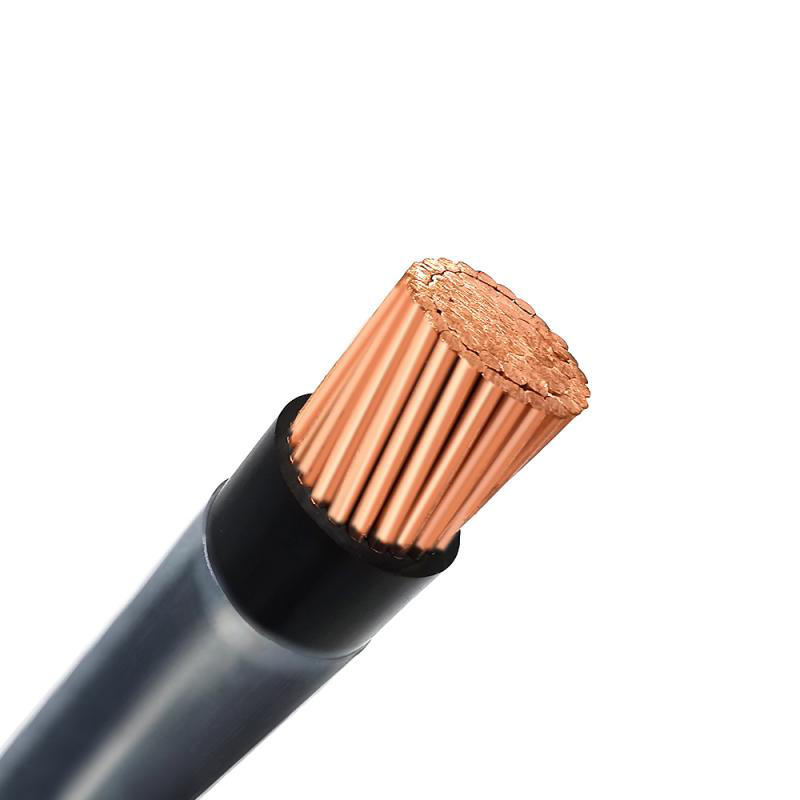

Conductor: Annealed copper conductor, solid/multiple strand

Insulation: TW PVC 60°C insulation

Color: Black, gray, other colors

Specifications

ASTM B3, B8UL62, UL 83 - Thermoplastic material insulated cableUL 1581 - Soft cable

Data Sheet

| SIZE | STRANDS STRANDING | SECTION | CONDUCTOR | INSULATION | INSULATION | DC | APPROX. | AMPACITY² | AMPACITY² | |

| AWG/ | No. | CLASS | (sqinches) | DIAMETER | THICKNESS | DIAMETER | RESISTANCE | TOTAL | (A)³ | (A)⁴ |

| komil | (mils) | (mils) | (mils) | AT 20℃1 | WEIGTH | |||||

| (ohm/kft) | (pound/kæl) | |||||||||

| 14 | 1 | Solid | 0.00323 | 64 | 30 | 127 | 2.53 | 18 | 25 | 20 |

| 12 | 1 | Solid | 0.00513 | 81 | 30 | 144 | 1.59 | 27 | 30 | 25 |

| 10 | 1 | Solid | 0.00815 | 102 | 30 | 165 | 1.00 | 40 | 40 | 30 |

| 8 | 1 | Solid | 0.0130 | 128 | 45 | 222 | 0.628 | 66 | 60 | 40 |

| 6 | 1 | Solid | 0.0206 | 162 | 60 | 287 | 0.395 | 107 | 80 | 55 |

| 4 | 1 | Solid | 0.0328 | 204 | 60 | 329 | 0.248 | 159 | 105 | 70 |

| 14 | 7 | B | 0.00323 | 70 | 30 | 133 | 2.58 | 19 | 25 | 20 |

| 12 | 7 | B | 0.00513 | 89 | 30 | 152 | 1.62 | 28 | 30 | 25 |

| 10 | 7 | B | 0.00815 | 112 | 30 | 175 | 1.02 | 42 | 40 | 30 |

| 8 | 7 | B | 0.0130 | 141 | 45 | 235 | 0.641 | 70 | 60 | 40 |

| 6 | 7 | B | 0.0206 | 178 | 60 | 303 | 0.403 | 113 | 80 | 55 |

| 4 | 7 | B | 0.0328 | 225 | 60 | 349 | 0.253 | 168 | 105 | 70 |

| 2 | 7 | B | 0.0521 | 283 | 60 | 408 | 0.159 | 253 | 140 | 95 |

| 1 | 19 | B | 0.0657 | 311 | 80 | 476 | 0.126 | 325 | 165 | 110 |

| 1/0 | 19 | B | 0.0829 | 349 | 80 | 514 | 0.100 | 400 | 195 | 125 |

| 2/0 | 19 | B | 0.105 | 392 | 80 | 557 | 0.0795 | 493 | 225 | 145 |

| 3/0 | 19 | B | 0.132 | 440 | 80 | 605 | 0.0630 | 609 | 260 | 165 |

| 4/0 | 19 | B | 0.166 | 494 | 80 | 659 | 0.0500 | 755 | 300 | 195 |

| 250 | 37 | B | 0.196 | 558 | 95 | 754 | 0.0423 | 906 | 340 | 215 |

| 300 | 37 | B | 0.236 | 611 | 95 | 807 | 0.0353 | 1072 | 375 | 240 |

| 350 | 37 | B | 0.275 | 661 | 95 | 856 | 0.0302 | 1237 | 420 | 260 |

| 400 | 37 | B | 0.314 | 706 | 95 | 902 | 0.0264 | 1402 | 455 | 280 |

| 500 | 37 | B | 0.393 | 789 | 95 | 985 | 0.0212 | 1729 | 515 | 320 |

| 600 | 61 | B | 0.471 | 866 | 110 | 1093 | 0.0176 | 2084 | 575 | 355 |

| 700 | 61 | B | 0.550 | 935 | 110 | 1162 | 0.0151 | 2411 | 630 | 385 |

| 750 | 61 | B | 0.589 | 968 | 110 | 1195 | 0.0141 | 2573 | 655 | 400 |

| 800 | 61 | B | 0.628 | 1000 | 110 | 1226 | 0.0132 | 2736 | 680 | 410 |

| 900 | 61 | B | 0.707 | 1061 | 110 | 1287 | 0.0118 | 3060 | 730 | 435 |

| 1000 | 61 | B | 0.785 | 1117 | 110 | 1344 | 0.0106 | 3384 | 780 | 455 |

Notes:1. DC resistance calculated based on a 10 371 ohm-cmilft resistivity for cooper.2. 60'C conductor temperature, 30'c ambient temperalure, According to NEC and NTc 2050, for sizes 14 12 and 10 AlG overload prolecionmust be 15. 20 and 30 A.3. One single conductor af free air at 30'C ambient iemperature.4. No more than three current carying conductors in a duct or in direct burial, 30'C ambient temperature.5. Acoording to NEC NTC 2050 the minimun size for use in Tray Cables must be 1/0 AlG for phase conductors, and 4 AwG for grounding conductors.6. Data herein indicated are approximated and are subject to normal manuracturing tolerances.