ASTM Standard XLPE Insulated LV Power Cable

Application

They are usually laid indoors, outdoors, in pipelines, cable trenches and loose soil.

Specifically approved for installation in cable trays per Article 340 of the NEC. Type TC cables are permitted for use in Class I Division 2 industrial hazardous locations per NEC. Cables may be installed in free air, raceways or direct burial, in wet or dry locations. All cables when used in accordance with the NEC, meet the requirements of OSHA.

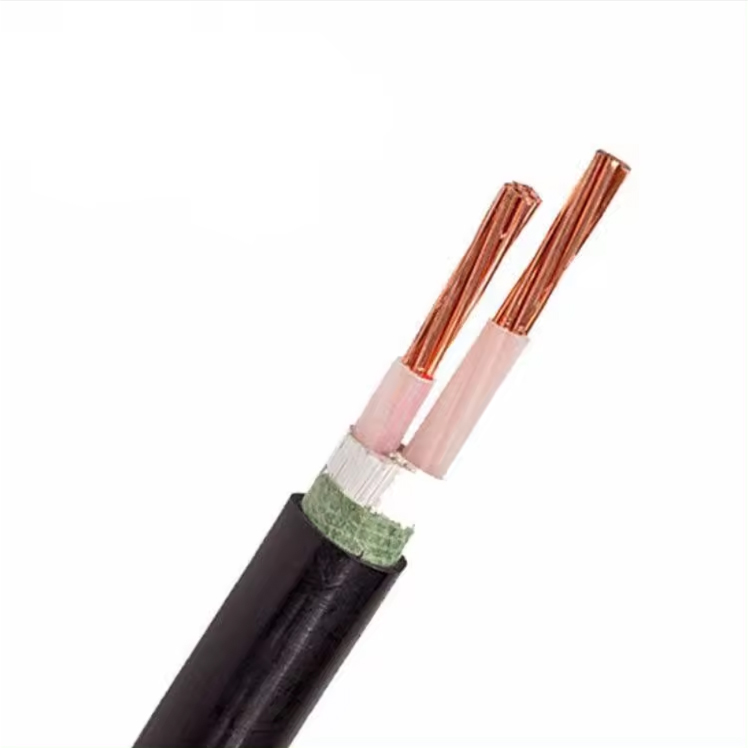

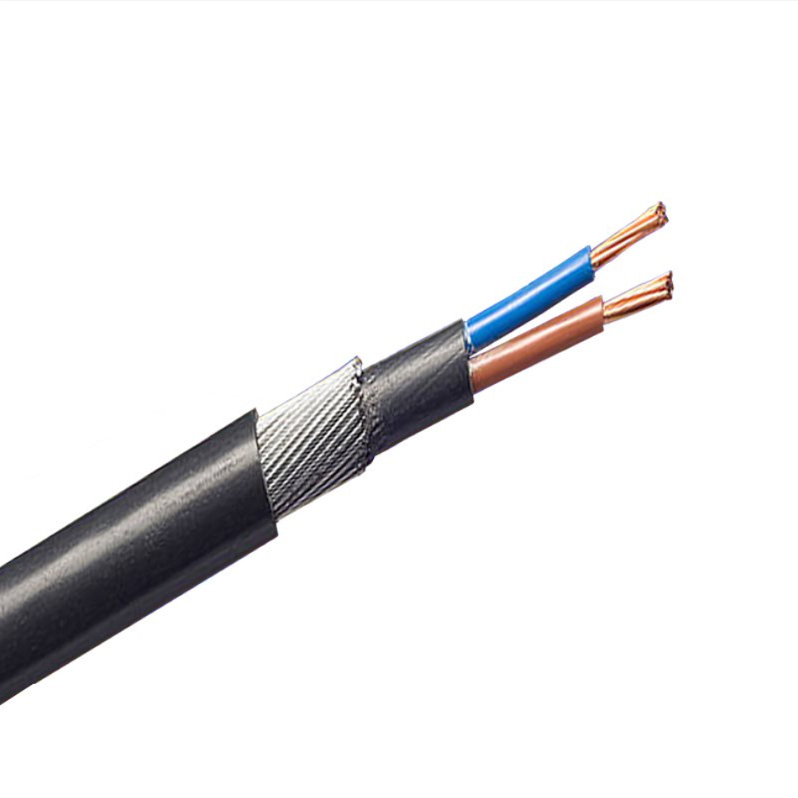

Construction

Stranded copper conductors, XLP (Cross-Linked Polyethylene) insulated, Method 1 - Table E1 or E2 color-coded, or Method 4 phase-identified. Insulated conductors cabled with a stranded copper grounding conductor in one interstice, cable tape, PVC (Polyvinyl Chloride) jacket, surface printed.

Standards

Conductors conform to ASTM B-3 & B-8.

Individual conductors conform to UL Standard 44, and are approved as Type XHHW-2.

TC Type Tray Cable per Article 340 of the NEC.

Cables suitable for Sunlight Resistant applications.

Cables designed to pass the IEEE-383 & IEEE-1202 flame tests.

Cables meet requirements of ICEA S-95-658/NEMA WC70.

Data Sheet

| HHW XLPE insulated power cable with aluminium conductor | |||||||||

| Conductor Size | Conductor Diameter | Insulation Thickness | Overall Diameter | Net Weight | Ampacity** at 75°C | Ampacity** at 90°C | |||

| AWG/KCMIL | inches |

mm |

inches | mm | inches | mm |

lbs/kft |

||

| 8 | 0.134 |

3.40 |

0.045 | 1.14 | 0.227 | 5.77 | 30 | 40 | 45 |

| 6 | 0.169 |

4.29 |

0.045 | 1.14 | 0.262 | 6.65 | 42 | 50 | 55 |

| 4 | 0.213 |

5.41 |

0.045 | 1.14 | 0.306 | 7.77 | 58 | 65 | 75 |

| 3 | 0.238 |

6.05 |

0.045 | 1.14 | 0.330 | 8.38 | 72 | 75 | 85 |

| 2 | 0.268 |

6.81 |

0.045 | 1.14 | 0.361 | 9.17 | 86 | 90 | 100 |

| 1 | 0.299 |

7.59 |

0.055 | 1.40 | 0.412 | 10.46 | 110 | 100 | 115 |

| 1/0 | 0.336 |

8.53 |

0.055 | 1.40 | 0.449 | 11.40 | 134 | 120 | 135 |

| 2/0 | 0.376 |

9.55 |

0.055 | 1.40 | 0.489 | 12.42 | 163 | 135 | 150 |

| 3/0 | 0.423 |

10.74 |

0.055 | 1.40 | 0.536 | 13.61 | 200 | 155 | 175 |

| 4/0 | 0.475 |

12.07 |

0.055 | 1.40 | 0.588 | 14.94 | 247 | 180 | 205 |

| 250 | 0.520 |

13.21 |

0.065 | 1.65 | 0.653 | 16.59 | 296 | 205 | 230 |

| 300 | 0.570 |

14.48 |

0.065 | 1.65 | 0.703 | 17.86 | 359 | 230 | 260 |

| 350 | 0.616 |

15.65 |

0.065 | 1.65 | 0.749 | 19.02 | 401 | 250 | 280 |

| 400 | 0.659 |

16.74 |

0.065 | 1.65 | 0.792 | 20.12 | 453 | 270 | 305 |

| 500 | 0.736 |

18.69 |

0.065 | 1.65 | 0.869 | 22.07 | 556 | 310 | 350 |

| 600 | 0.813 |

20.65 |

0.080 | 2.03 | 0.979 | 24.87 | 679 | 340 | 385 |

| 700 | 0.877 |

22.28 |

0.080 | 2.03 | 1.040 | 26.42 | 782 | 375 | 425 |

| 750 | 0.908 |

23.06 |

0.080 | 2.03 | 1.071 | 27.20 | 833 | 385 | 435 |

| 900 | 0.999 |

25.37 |

0.080 | 2.03 | 1.169 | 29.69 | 983 | 425 | 480 |

| 1000 | 1.060 |

26.92 |

0.080 | 2.03 | 1.223 | 31.06 |

1090 |

445 | 500 |

| XHHW XLPE insulated power cable with copper conductor | |||||||

| Conductor Size | No. of Strands | Insulation Thickness | Overall Diameter | Net Weight | Ampacity* | ||

| AWG/kcmil | inches | mm | inches | mm | lbs/kft | amps | |

| 14 | 7 | 0.030 | 0.76 | 0.140 | 3.56 | 18 | 25** |

| 12 | 7 | 0.030 | 0.76 | 0.160 | 4.06 | 27 | 30** |

| 10 | 7 | 0.030 | 0.76 | 0.180 | 4.57 | 39 | 40** |

| 8 | 7 | 0.045 | 1.14 | 0.240 | 6.10 | 64 | 55 |

| 6 | 7 | 0.045 | 1.14 | 0.280 | 7.11 | 97 | 75 |

| 4 | 7 | 0.045 | 1.14 | 0.320 | 8.13 | 149 | 95 |

| 2 | 7 | 0.045 | 1.14 | 0.380 | 9.65 | 230 | 130 |

| 1 | 19 | 0.055 | 1.40 | 0.440 | 11.18 | 291 | 145 |

| 1/0 | 19 | 0.055 | 1.40 | 0.480 | 12.19 | 366 | 170 |

| 2/0 | 19 | 0.055 | 1.40 | 0.520 | 13.21 | 456 | 195 |

| 3/0 | 19 | 0.055 | 1.40 | 0.580 | 14.73 | 569 | 225 |

| 4/0 | 19 | 0.055 | 1.40 | 0.630 | 16.00 | 711 | 260 |

| 250 | 37 | 0.065 | 1.65 | 0.710 | 18.03 | 835 | 290 |

| 350 | 37 | 0.065 | 1.65 | 0.810 | 20.57 | 1,155 | 350 |

| 500 | 37 | 0.065 | 1.65 | 0.930 | 23.62 | 1,631 | 430 |

| 750 | 61 | 0.080 | 2.03 | 1.150 | 29.21 | 2,441 | 520 |

| 1000 | 61 | 0.080 | 2.03 | 1.320 | 33.53 | 3,233 | 615 |