ASTM Standard PVC Insulated LV Power Cable

Application

PVC Insulated LV Power Cable used for control and power applications in chemical plants, industrial plants, utility substations and generating stations, residential and commercial buildings.

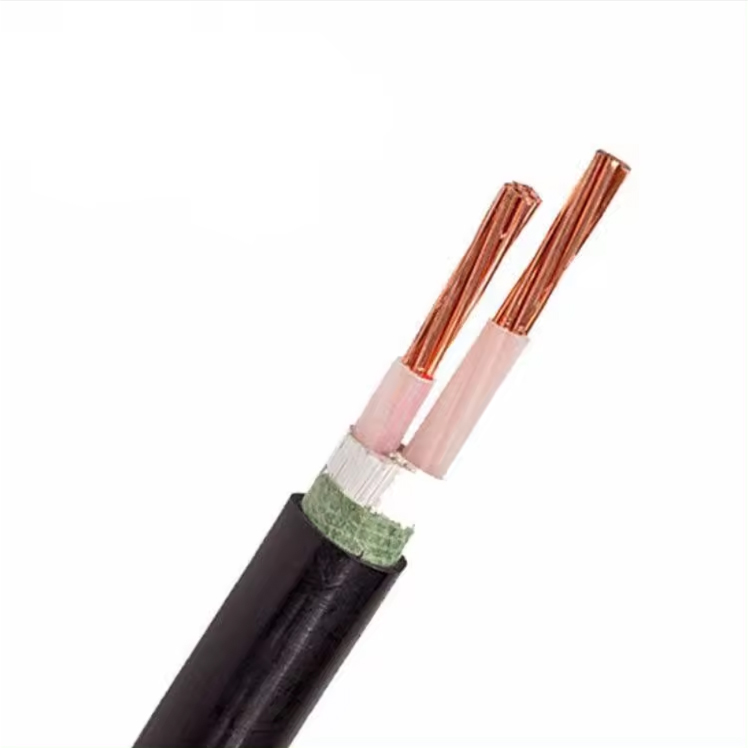

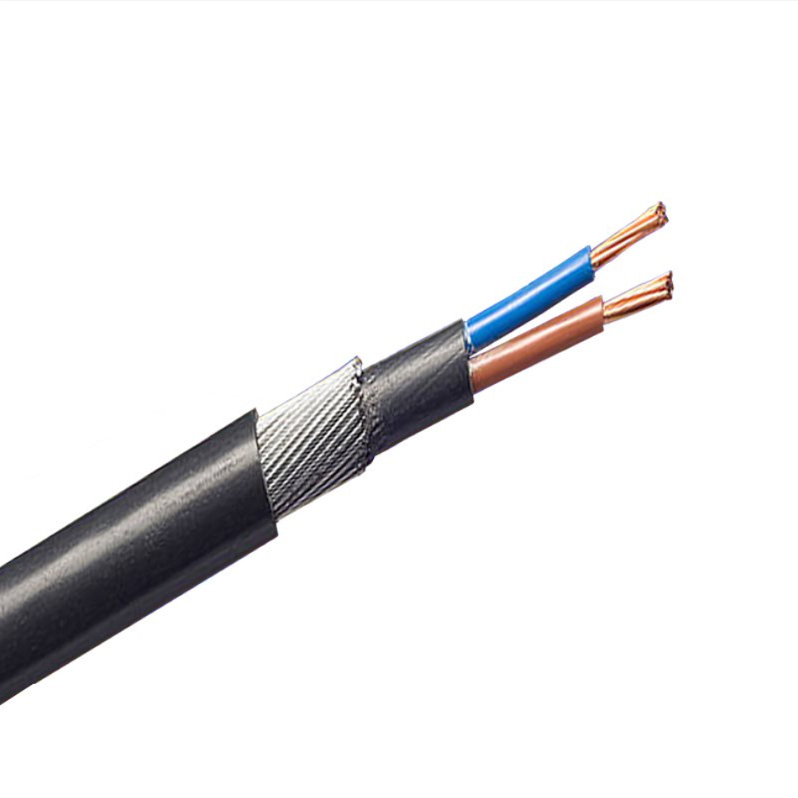

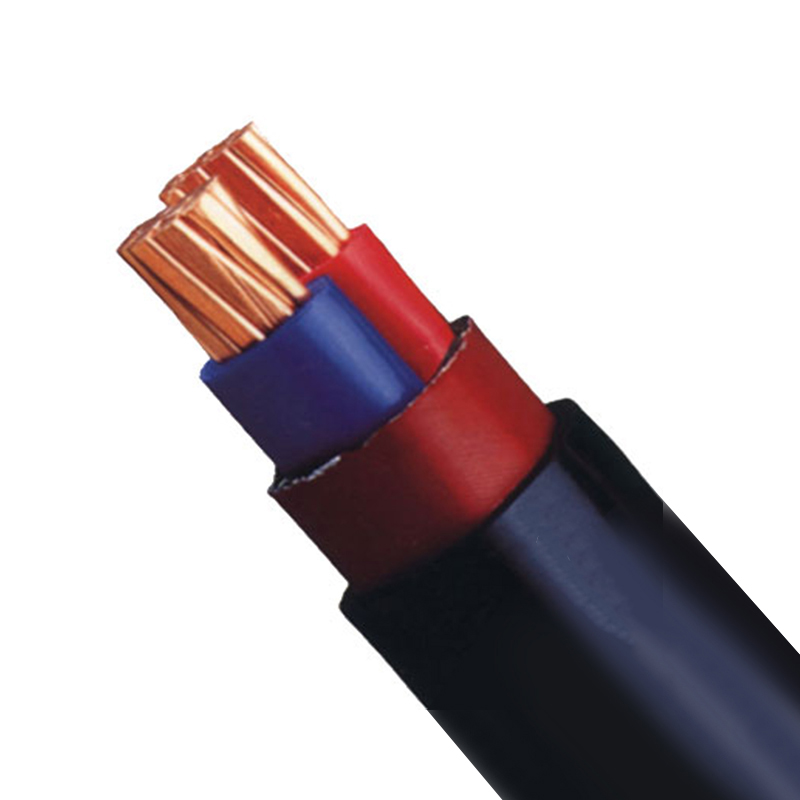

Construction

1. Conductor: Class B stranded, annealed bare copper per ASTM B-3 and B-8

2. insulation: Polyvinyl Chloride (PVC), nylon covered per UL 83 for Type THHN/THWN

3. Color code: Conductors are color coded per ICEA Method 4 (printed numbers)

4. Assembly: Insulated conductors are cabled together with fillers as necessary to make round

5. Overall jacket: Sunlight-resistant Polyvinyl Chloride (PVC) per UL 1277

Standards

ASTM B3 Standard Specification for Soft or Annealed Copper Wire

ASTM B8 Concentric-Lay-Stranded Copper Conductors

UL 83 Thermoplastic Insulated Wires and Cables

UL 1277 Electrical Power and Control Tray Cables

UL 1685 Vertical-Tray Fire Propagation and Smoke Release Test

ICEA S-58-679 Control Cable Conductor Identification Method 3 (1-BLACK, 2-RED, 3-BLUE)

ICEA S-95-658 (NEMA WC70) Power Cables Rated 2000 Volts or Less for the Distribution of Electrical Energy

Product Data Sheet

| Nominal Dia. for Copper and Aluminum Conductors | |||||||

| Conductor size | Solid (mm) | Stranded | |||||

| AWG or KCMIL | mm² | Compact (mm) | Class B Compressed | Class B | Class C | Class D | |

| 18 | 0.823 | 1.02 | \ | \ | 1.17 | \ | \ |

| 16 | 1.31 | 1.29 | \ | \ | 1.47 | \ | \ |

| 15 | 1.65 | 1.45 | \ | \ | 1.65 | \ | \ |

| 14 | 2.08 | 1.63 | \ | 1.79 | 1.84 | 1.87 | 1.87 |

| 13 | 2.63 | 1.83 | \ | 2.02 | 2.07 | 2.10 | 2.10 |

| 12 | 3.31 | 2.05 | \ | 2.26 | 2.32 | 2.35 | 2.36 |

| 11 | 4.17 | 2.30 | \ | 2.53 | 2.62 | 2.64 | 2.64 |

| 10 | 5.26 | 2.59 | \ | 2.87 | 2.95 | 2.97 | 2.97 |

| 9 | 6.63 | 2.91 | \ | 3.20 | 3.30 | 3.33 | 3.35 |

| 8 | 8.37 | 3.26 | 3.40 | 3.58 | 3.71 | 3.76 | 3.76 |

| 7 | 10.60 | 3.67 | \ | 4.01 | 4.17 | 4.22 | 4.22 |

| 6 | 13.30 | 4.11 | 4.29 | 4.52 | 4.67 | 4.72 | 4.72 |

| 5 | 16.80 | 4.62 | \ | 5.08 | 5.23 | 5.28 | 5.31 |

| 4 | 21.10 | 5.19 | 5.41 | 5.72 | 5.89 | 5.94 | 5.97 |

| 3 | 26.7 | 5.83 | 6.05 | 6.40 | 6.60 | 6.68 | 6.71 |

| 2 | 33.6 | 6.54 | 6.81 | 7.19 | 7.42 | 7.52 | 7.54 |

| 1 | 42.4 | 7.35 | 7.59 | 8.18 | 8.43 | 8.46 | 8.46 |

| 1/0 | 53.5 | 8.25 | 8.53 | 9.17 | 9.45 | 9.50 | 9.50 |

| 2/0 | 37.4 | 9.27 | 9.55 | 10.30 | 10.60 | 10.70 | 10.70 |

| 3/0 | 85 | 10.40 | 10.70 | 11.6 | 11.9 | 12.0 | 12.00 |

| 4/0 | 107 | 11.70 | 12.10 | 13.0 | 13.4 | 13.4 | 13.45 |

| 250 | 127 | 12.70 | 13.20 | 14.2 | 14.6 | 14.6 | 14.60 |

| 300 | 152 | 13.90 | 14.50 | 15.5 | 16.0 | 16.0 | 16.00 |

| 350 | 177 | 15.00 | 15.60 | 16.8 | 17.3 | 17.3 | 17.30 |

| 400 | 203 | 16.10 | 16.70 | 17.9 | 18.5 | 18.5 | 18.5 |

| 450 | 228 | 17.00 | 17.80 | 19.0 | 19.6 | 19.6 | 19.6 |

| 500 | 253 | 18.00 | 18.70 | 20.0 | 20.7 | 20.7 | 20.7 |

| 550 | 279 | \ | 19.70 | 21.1 | 21.7 | 21.7 | 21.7 |

| 600 | 304 | \ | 20.70 | 22.0 | 22.7 | 22.7 | 22.7 |

| 650 | 329 | \ | 21.50 | 22.9 | 23.6 | 23.6 | 23.60 |

| 700 | 355 | \ | 22.30 | 23.7 | 24.5 | 24.5 | 24.50 |

| 750 | 380 | \ | 23.10 | 24.6 | 25.3 | 25.4 | 25.43 |

| 800 | 405 | \ | 23.80 | 25.4 | 26.2 | 26.2 | 26.20 |

| 900 | 456 | \ | 25.40 | 26.9 | 27.8 | 27.8 | 27.80 |

| 1000 | 507 | \ | 26.90 | 28.4 | 29.3 | 29.3 | 29.30 |

| 1100 | 557 | \ | \ | 29.8 | 30.7 | 30.7 | 30.78 |

| 1200 | 608 | \ | \ | 31.1 | 32.1 | 32.1 | 32.10 |

| 1250 | 633 | \ | \ | 31.8 | 32.7 | 32.8 | 32.80 |

| 1300 | 659 | \ | \ | 32.4 | 33.4 | 33.4 | 33.40 |

| 1400 | 709 | \ | \ | 33.6 | 34.7 | 34.7 | 34.7 |

| 1500 | 760 | \ | \ | 34.8 | 35.9 | 35.9 | 35.9 |

| 1600 | 811 | \ | \ | 35.9 | 37.1 | 37.1 | 37.1 |

| 1700 | 861 | \ | \ | 37.1 | 38.2 | 38.2 | 38.2 |

| 1750 | 887 | \ | \ | 37.60 | 38.8 | 38.8 | 38.8 |

| 1800 | 912 | \ | \ | 38.2 | 39.3 | 39.3 | 39.3 |

| 1900 | 963 | \ | \ | 39.2 | 40.4 | 40.4 | 40.4 |

| 2000 | 1013 | \ | \ | 40.2 | 41.5 | 41.5 | 41.5 |

| 2500 | 1267 | \ | \ | 44.9 | 46.3 | 46.3 | 46.3 |

| 3000 | 1520 | \ | \ | 49.2 | 50.7 | 50.7 | 50.7 |

| Conductor Sizes, Insulation Thickness and Test Voltages | |||||

| Rated Circuit Voltage (Phase to Phase) | Conductor size | Nominal Insulation Thickness | AC Test voltage | DC Test Voltage | |

| A | B | ||||

| V | AWG/ KCMIL | mm | KV | KV | |

| 0-600 | 43357.00 | 1.016 | 0.762 | 3.5 | 10.5 |

| 43314.00 | 1.397 | 1.143 | 5.5 | 16.5 | |

| 1-4/0 | 2.032 | 1.397 | 7 | 21 | |

| 225-500 | 2.413 | 1.651 | 8 | 24 | |

| 525-1000 | 2.64 | 2.032 | 10 | 30 | |

| 1025-2000 | 3.175 | 2.54 | 11.5 | 34 | |

| 601-2000 | 43357.00 | 1.397 | 1.016 | 5.5 | 16.5 |

| 43314.00 | 1.778 | 1.397 | 7 | 21 | |

| 1-4/0 | 2.159 | 1.651 | 8 | 24 | |

| 225-500 | 2.667 | 1.778 | 9.5 | 28.5 | |

| 525-1000 | 3.048 | 2.159 | 11.5 | 34.5 | |

| 1025-2000 | 3.556 | 2.921 | 13.5 | 40 | |

| Jacket Thickness | |||||

| Jacket thickness for Single-conductor cables | Thickness of common overall jacket of multiple-conductor cable | ||||

| Calculated dia. of cable under jacket | Jacket Thickness | Calculated dia. of cable under jacket | Jacket Thickness | ||

| Min. | Nominal | Min. | Nominal | ||

| mm | mm | mm | mm | mm | mm |

| 6.35 or less | 0.33 | 0.38 | 10.8 or less | 1.02 | 1.14 |

| 6.38-10.8 | 0.635 | 0.76 | 10.82-17.78 | 1.27 | 1.52 |

| 10.82-17.78 | 1.02 | 1.14 | 17.81-38.10 | 1.78 | 2.03 |

| 17.81-38.1 | 1.4 | 1.65 | 38.13-63.50 | 2.41 | 2.79 |

| 38.13-63.5 | 2.03 | 2.41 | 63.53 and larger | 3.05 | 3.56 |

| 63.53 & later | 2.67 | 3.18 | |||