AS/NZS standard 6.35/11kV XLPE Insulated MV Medium Voltage Power Cable

Description

Construction with higher fault current ratings are available on request. Suitable for static applications on the ground, inside and outside facilities, outdoors, in cable trenches, in water, and where the cables are not exposed to heavy mechanical stress and tensile strains. Because its dielectric loss coefficient is very low and remains constant throughout its service life, and because the XLPE material has excellent insulation properties and is firmly longitudinally spliced with the conductor shield and insulation shield of the semiconductor material (one molding), the cable operation has high reliability . Widely used in transformer stations, electric power plants and industrial plants etc.

A global manufacturer of medium voltage(MV) underground cable supplies a full variety of medium voltage(MV) underground cable and tailed electric cables from our stock.

Application

Electricity distribution or sub-transmission network cables are commonly used as the main supply for commercial, industrial and urban residential networks. Suitable for high fault level systems with current ratings up to 10kA/1sec. Construction with higher fault current ratings are available on request.

Temperature range

| Installation min temperature | 0°C |

| Operating max temperature | +90°C |

| Operating min temperature | -25 °C |

| Minimum bending radius | |

| Installed cables | 12D (PVC only) 15D (HDPE) |

| During installation | 18D (PVC only) 25D (HDPE) |

| Resistance to Chemical exposure | Accidental |

| Mechanical impact | Light (PVC only) Heavy (HDPE) |

| Water exposure | XLPE – Spray EPR – Immersion/Temporary coverage |

| Solar radiation and weather exposure | Suitable for direct exposure. |

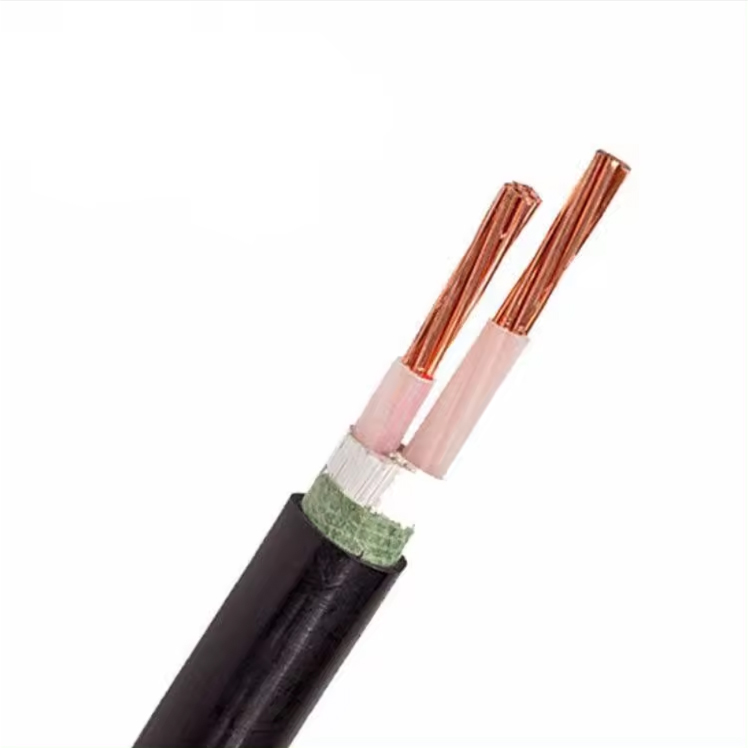

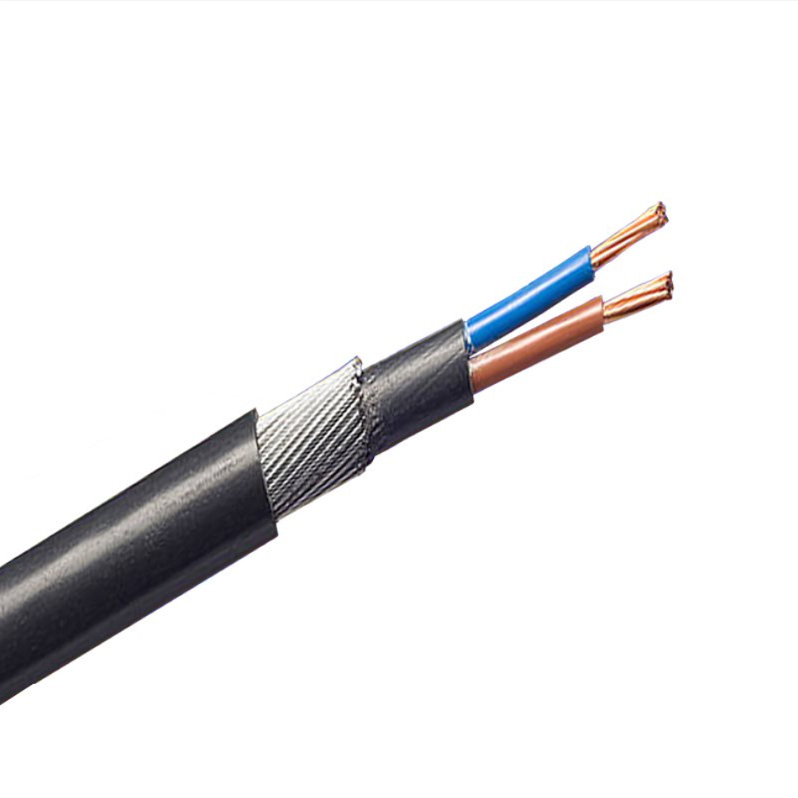

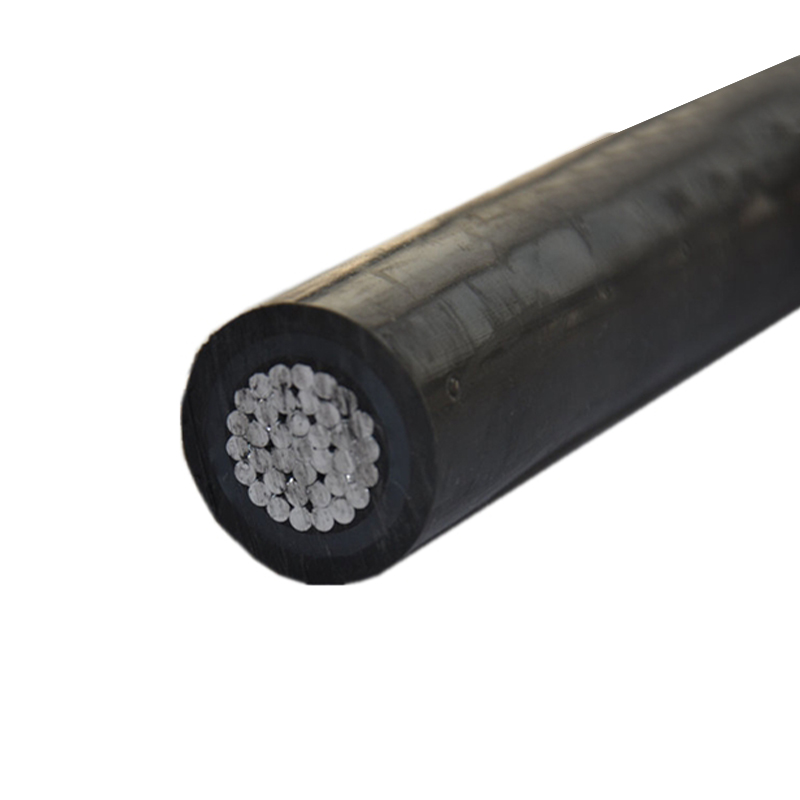

Construction

Manufactured and Type Tested AS/NZS 1429.1, IEC: 60502-2 and other applicable standardsFormation: 1 core, 3 core, 3×1 core TriplexConductor: Cu or AL, Stranded Circular, Stranded Compact Circular, Milliken SegmentedInsulation: XLPE / TR-XLPE / EPRMetallic screen or sheath: Copper Wire Screen (CWS), Copper Tape Screen (CTS), Lead alloy sheath (LAS), Corrugated Aluminium sheath (CAS), Corrugated Copper sheath (CCU), Corrugated Stainless Steel (CSS), Aluminium poly laminated (APL), Copper Poly Laminated (CPL), Aldrey wire screen (AWS)Armour: Aluminium Wire Armoured (AWA), Steel Wire Armoured (SWA), Stainless Steel Wire Armoured (SSWA)Termite Protection : Polyamide Nylon Jacket, Double brass tape (DBT), CypermethrinBlack 5V-90 polyvinyl chloride (PVC) : standardOrange 5V-90 PVC inner plus black high densitypolyethylene (HDPE) outer : alternativeLow smoke zero halogen (LSOH) : alternative

Data Sheet

6.35/11kV-Power cable

| Cores x Nominal Area | Conductor diameter (Approx.) | Nominal Insulation Thickness | Approx. CWS area on each core | Nominal Thickness of PVC Sheath | Overall Cable diameter (+/- 3.0) | Short Circuit rating of Conductor/ CWS | Cable Weight (Approx.) | Max. Conductor DC Resistance at 20 °C |

| No. X mm2 | mm | mm | mm2 | mm | mm | kA for 1sec | kg/km | (Ω/km) |

| 1C x 35 | 7.0 | 3.4 | 24 | 1.8 | 23.6 | 5 / 3 | 1044 | 0.524 |

| 1C x 50 | 8.1 | 3.4 | 24 | 1.8 | 24.7 | 7.2 / 3 | 1205 | 0.387 |

| 1C x 70 | 9.7 | 3.4 | 79 | 1.8 | 28.4 | 10 / 10 | 1955 | 0.268 |

| 1C x 95 | 11.4 | 3.4 | 79 | 1.8 | 30.1 | 13.6 / 10 | 2219 | 0.193 |

| 1C x 120 | 12.8 | 3.4 | 79 | 1.9 | 31.4 | 17.2 / 10 | 2480 | 0.153 |

| 1C x 150 | 14.2 | 3.4 | 79 | 1.9 | 32.8 | 21.5 / 10 | 2794 | 0.124 |

| 1C x 185 | 16.1 | 3.4 | 79 | 2.0 | 34.3 | 26.5 / 10 | 3146 | 0.0991 |

| 1C x 240 | 18.5 | 3.4 | 79 | 2.0 | 36.5 | 34.3 / 10 | 3698 | 0.0754 |

| 1C x 300 | 20.6 | 3.4 | 79 | 2.1 | 38.6 | 42.9 / 10 | 4307 | 0.0601 |

| 1C x 400 | 23.6 | 3.4 | 79 | 2.2 | 42.0 | 57.2 / 10 | 5295 | 0.0470 |

| 1C x 500 | 26.6 | 3.4 | 79 | 2.3 | 45.2 | 71.5 / 10 | 6280 | 0.0366 |

| 1C x 630 | 30.2 | 3.4 | 79 | 2.4 | 49.0 | 90.1 / 10 | 7550 | 0.0283 |