AS/NZS standard 12.7kV/22kV-XLPE Insulated MV Medium Voltage Power Cable

Application

Power distribution or secondary transmission network cable are commonly used as main supply for Commercial, Industrial and urban residential networks. Suitable for high fault level systems rated up to 10kA/sec. Can provide structures with higher fault current ratings upon request.

Temperature range

Installation min temperature |

0°C |

Working max temperature |

+90°C |

Working min temperature |

-25 °C |

Min bending radius | |

Install cable |

12D (PVC) 15D (HDPE) |

During installation |

18D (PVC) 25D (HDPE) |

Resistance to Chemical exposure |

Accidental |

Mechanical impact |

Light (PVC only) Heavy (HDPE) |

Water exposure |

XLPE – Spray EPR – Immersion/Temporary coverage |

Solar radiation and weather exposure |

can be direct exposure. |

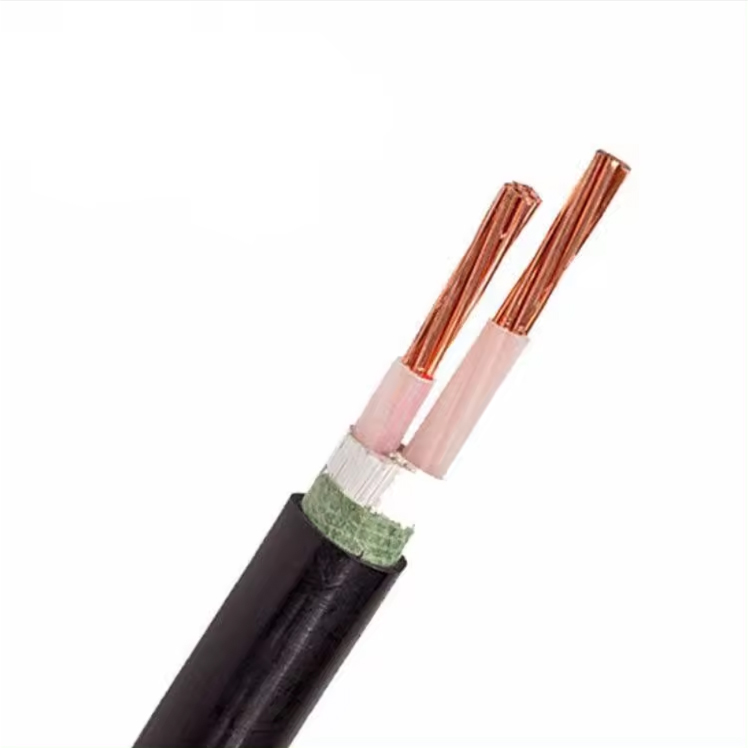

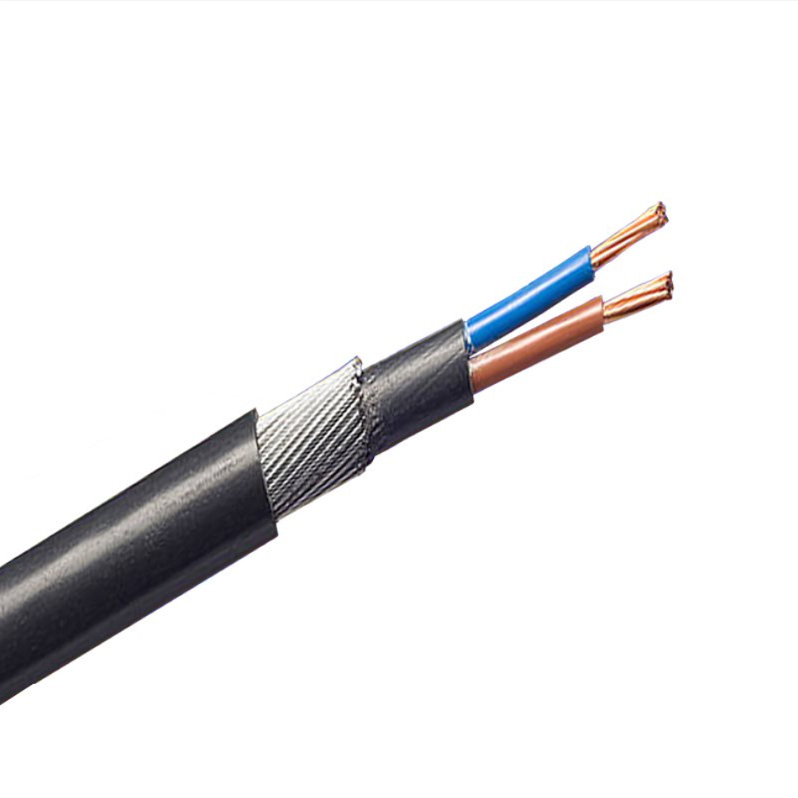

Construction

Manufacturing and type testing in accordance with AS/NZS 1429.1, IEC: 60502-2 or equivalent

Structure: 1 core, 3 core, 3×1 core Triplex

Conductor: Cu or AL, Stranded Circular, twisted Compact Circular, Milliken Segmented

Insulation: XLPE / TR-XLPE / EPR

Metallic screen or sheath: Copper Wire shielding (CWS), Copper Tape shielding (CTS), Lead alloy sheath (LAS), Corrugated Aluminium sheath (CAS), Corrugated Copper sheath (CCU), Corrugated Stainless Steel (CSS), Aluminum polymer lamination (APL), Copper Polymer Lamination (CPL), Aldrey wire screen (AWS)

Armour: Aluminium Wire Armour (AWA), Steel Wire Armour (SWA), Stainless Steel Wire Armour (SSWA)

Anti termite:Poly amide Nylon Jacket, Double brass tape (DBT), Cypermethrin

Black 5V-90 polyvinyl chloride (PVC): standard

Orange 5V-90 PVC inner layer with black high density

Polyethylene (HDPE) outer layer– alternative

Low smoke zero halogen (LSOH) – alternative

Data Sheet

12.7/22kV Power cable

|

Cores x Nominal Area |

Conductor diameter (Approx.) |

Nominal Insulation Thickness |

Approx. CWS area on each core |

Nominal Thickness of PVC Sheath |

Overall Cable diameter (+/- 3.0) |

Short Circuit rating of Conductor/ CWS |

Cable Weight (Approx.) |

Max. Conductor DC Resistance at 20 °C |

|

No. X mm2 |

mm |

mm |

mm2 |

mm |

mm |

kA for 1sec |

kg/km |

(Ω/km) |

|

1C x 35 |

7.0 | 5.5 | 24 | 1.8 | 27.5 | 5 / 3 | 1200 | 0.524 |

|

1C x 50 |

8.1 | 5.5 | 24 | 1.8 | 28.6 | 7.2 / 3 | 1367 | 0.387 |

|

1C x 70 |

9.7 | 5.5 | 79 | 1.9 | 32.1 | 10 / 10 | 2130 | 0.268 |

|

1C x 95 |

11.4 | 5.5 | 79 | 2.0 | 33.8 | 13.6 / 10 | 2421 | 0.193 |

|

1C x 120 |

12.8 | 5.5 | 79 | 2.0 | 35.2 | 17.2 / 10 | 2687 | 0.153 |

|

1C x 150 |

14.2 | 5.5 | 79 | 2.1 | 36.6 | 21.5 / 10 | 3018 | 0.124 |

|

1C x 185 |

16.1 | 5.5 | 79 | 2.1 | 38.3 | 26.5 / 10 | 3395 | 0.0991 |

|

1C x 240 |

18.5 | 5.5 | 79 | 2.2 | 40.9 | 34.3 / 10 | 3979 | 0.0754 |

|

1C x 300 |

20.6 | 5.5 | 79 | 2.3 | 43.2 | 42.9 / 10 | 4599 | 0.0601 |

|

1C x 400 |

23.6 | 5.5 | 79 | 2.4 | 46.6 | 57.2 / 10 | 5613 | 0.047 |

|

1C x 500 |

26.6 | 5.5 | 79 | 2.5 | 49.8 | 71.5 / 10 | 6621 | 0.0366 |

|

1C x 630 |

30.2 | 5.5 | 79 | 2.6 | 53.6 | 90.1 / 10 | 7918 | 0.0283 |