ACSR Aluminum Conductor Steel reinforced Cables IEC 61089 Standard

Applications

Aluminum conductor steel reinforced cables are appropriate for various spans on transmission towers, wooden poles, and other structures. Its applications range from extended, extra high voltage (EHV) transmission lines to sub-service spans at utilization or distribution voltages within private properties.

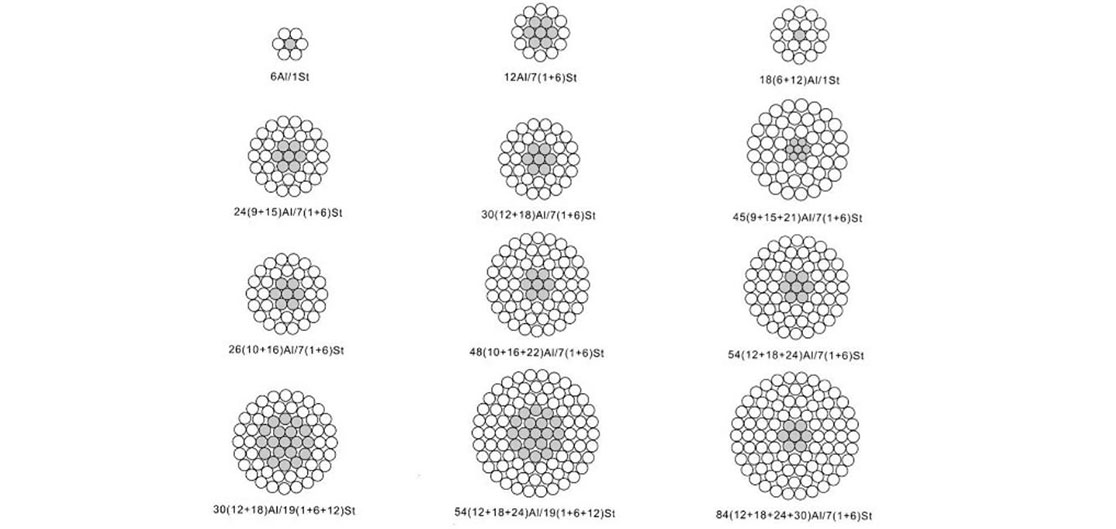

Construction

ACSR Steel Reinforced Aluminium Conductor are formed by several wires of aluminium and galvanized steel, stranded in concentric layers. The wire or wires which form the core, are made of galvanized steel and the external layer or layers, are of aluminium. Galvanized steel core consist normally of 1, 7 or 19 wires.

Feature

ACSR (aluminum conductor steel-reinforced) has a long service record because of its economy, dependability, and strength to weight ratio. The combined light weight and high conductivity of aluminum with strength of the steel core enables higher tensions, less sag, and longer spans than any alternative.

Electrical Properties

| Density at 20°C | Aluminium: 2.703 kg/dm |

| Galvanized Steel | 7.80 kg/dm |

| Temperature Coefficient at 20°C | Aluminium: 0.00403 (°C) |

| Resistivity at 20°C | Aluminium: Should not exceed 0.028264 |

| Linear Expansivity | Aluminium: 23 x10 (°C) |

| Galvanized Steel | 11.5 x10 (1/°C) |

Standard

BS EN 50182, IEC 61089, ASTM B 232/B 232M, AS/NZS 3607, GB/T 1179, BS 215-2, DIN 48204, CSA C 61089, GOST 839, JIS 3110, etc.

Packing material

Wooden drum, steel-wooden drum, steel drum.

Specification

IEC 61089 Specifications for Round wire concentric lay overhead electrical stranded conductors

Specifications

ACSR Aluminum Conductor Steel reinforced Cables IEC 61089 Standard Parameters

| Code | Nominal Area | Stranding | Overall Diameter | Weight | Breakign Load | Electrical Resistance at 20°C | Current Rating* | |||

| AL | Steel | Total | AL | Steel | ||||||

| mm² | mm² | mm² | No./mm | No./mm | mm | Kg/Km | KN | Ω/KM | A | |

| 16 | 16 | 2.67 | 18.7 | 6/1.84 | 1/1.84 | 5.52 | 64.6 | 6.08 | 1.7934 | 85 |

| 25 | 25 | 4.17 | 29.2 | 6/2.30 | 1/2.30 | 6.9 | 100.9 | 9.13 | 1.1478 | 112 |

| 40 | 40 | 6.67 | 46.7 | 6/2.91 | 1/2.91 | 8.73 | 161.5 | 14.4 | 0.7174 | 150 |

| 63 | 63 | 10.5 | 73.5 | 6/3.66 | 1/3.66 | 10.98 | 254.4 | 21.63 | 0.4555 | 198 |

| 100 | 100 | 16.7 | 117 | 6/4.61 | 1/4.61 | 13.83 | 403.8 | 34.33 | 0.2869 | 263 |

| 125 | 125 | 6.94 | 132 | 18/2.97 | 1/2.97 | 14.85 | 397.9 | 29.17 | 0.2304 | 299 |

| 125 | 125 | 20.4 | 145 | 26/2.47 | 7/1.92 | 15.64 | 503.9 | 45.69 | 0.231 | 302 |

| 160 | 160 | 8.89 | 169 | 18/3.36 | 1/3.36 | 16.8 | 509.3 | 36.18 | 0.18 | 347 |

| 160 | 160 | 26.1 | 186 | 26/2.80 | 7/2.18 | 17.74 | 644.9 | 57.69 | 0.1805 | 351 |

| 200 | 200 | 11.1 | 211 | 18/3.76 | 1/3.76 | 18.8 | 636.7 | 44.22 | 0.144 | 398 |

| 200 | 200 | 32.6 | 233 | 26/3.13 | 7/2.43 | 19.81 | 806.2 | 70.13 | 0.1444 | 402 |

| 250 | 250 | 24.6 | 275 | 22/3.80 | 7/2.11 | 21.53 | 880.6 | 68.72 | 0.1154 | 458 |

| 250 | 250 | 40.7 | 291 | 26/3.50 | 7/2.72 | 22.16 | 1007.7 | 87.67 | 0.1155 | 461 |

| 315 | 315 | 21.8 | 337 | 45/2.99 | 7/1.99 | 23.91 | 1039.6 | 79.03 | 0.0917 | 526 |

| 315 | 315 | 51.3 | 366 | 26/3.93 | 7/3.05 | 24.87 | 1269.7 | 106.83 | 0.0917 | 530 |

| 400 | 400 | 27.7 | 428 | 45/3.36 | 7/2.24 | 26.88 | 1320.1 | 98.36 | 0.0722 | 607 |

| 400 | 400 | 51.9 | 452 | 54/3.07 | 7/3.07 | 27.63 | 1510.3 | 123.04 | 0.0723 | 610 |

| 450 | 450 | 31.1 | 481 | 45/3.57 | 7/2.38 | 28.56 | 1485.2 | 107.47 | 0.0642 | 651 |

| 450 | 450 | 58.3 | 508 | 54/3.26 | 7/3.26 | 29.34 | 1699.1 | 138.42 | 0.0643 | 655 |

| 500 | 500 | 34.6 | 535 | 45/3.76 | 7/2.51 | 30.09 | 1650.2 | 119.41 | 0.0578 | 693 |

| 500 | 500 | 64.8 | 565 | 54/3.43 | 7/3.43 | 30.87 | 1887.9 | 153.8 | 0.0578 | 697 |

| 560 | 560 | 38.7 | 599 | 45/3.98 | 7/2.65 | 31.83 | 1848.2 | 133.74 | 0.0516 | 741 |

| 560* | 560 | 70.9 | 631 | 54/3.63 | 19/2.18 | 32.68 | 2103.4 | 172.59 | 0.0516 | 745 |

| 630 | 630 | 43.6 | 674 | 45/4.22 | 7/2.81 | 33.75 | 2079.2 | 150.45 | 0.0459 | 794 |

| 630* | 630 | 79.8 | 710 | 54/3.85 | 19/2.31 | 34.65 | 2366.3 | 191.77 | 0.0459 | 798 |

| 710 | 710 | 49.1 | 759 | 45/4.48 | 7/2.99 | 35.85 | 2343.2 | 169.56 | 0.0407 | 851 |

| 710* | 710 | 89.9 | 800 | 54/4.09 | 19/2.45 | 36.79 | 2666.8 | 216.12 | 0.0407 | 856 |

| 800* | 800 | 34.6 | 835 | 72/3.76 | 7/2.51 | 37.61 | 2480.2 | 167.41 | 0.0361 | 910 |

| 800* | 800 | 66.7 | 867 | 84/3.48 | 7/3.48 | 38.28 | 2732.7 | 205.33 | 0.0362 | 912 |

| 800* | 800 | 101 | 901 | 54/4.34 | 19/2.61 | 39.09 | 3004.9 | 243.52 | 0.0362 | 916 |

| 900* | 900 | 38.9 | 939 | 72/3.99 | 7/2.66 | 39.9 | 2790.2 | 188.33 | 0.0321 | 972 |

| 900* | 900 | 75 | 975 | 84/3.69 | 7/3.69 | 40.59 | 3074.2 | 226.5 | 0.0322 | 974 |

| 1000* | 1000 | 43.2 | 1043 | 72/4.21 | 7/2.80 | 42.08 | 3100.3 | 209.26 | 0.0289 | 1031 |

| 1120* | 1120 | 47.3 | 1167 | 72/4.45 | 19/1.78 | 44.5 | 3464.9 | 234.53 | 0.0258 | 1096 |

| 1120* | 1120 | 91.2 | 1211 | 84/4.12 | 19/2.47 | 45.31 | 3811.5 | 283.17 | 0.0258 | 1100 |

| 1250* | 1250 | 102 | 1352 | 84/4.35 | 19/2.61 | 47.85 | 4253.9 | 316.04 | 0.0232 | 1165 |

| 1250* | 1250 | 52.8 | 1303 | 72/4.70 | 19/1.88 | 47 | 3867.1 | 261.75 | 0.0231 | 1163 |

The items marked with * are not in our current product range and the details are for information only.

Note: The values of current rating mentioned in above Table are based on wind velocity of 0.6 metre/second, solar heat radiation of 1200 watt/metre2, ambient temperature of 50°C & conductor temperature of 80°C.