AAAC All Aluminium Alloy Conductor IEC 61089 Standard

Applications

AAAC Aluminium Alloy Conductors are used for primary and secondary overhead power transmission lines having long spans and high resistance to corrosion.

AAAC Aluminium Alloy Conductor cables offer excellent electrical characteristics, excellent sag-tension characteristics and superior corrosion resistance to that of ACSR.

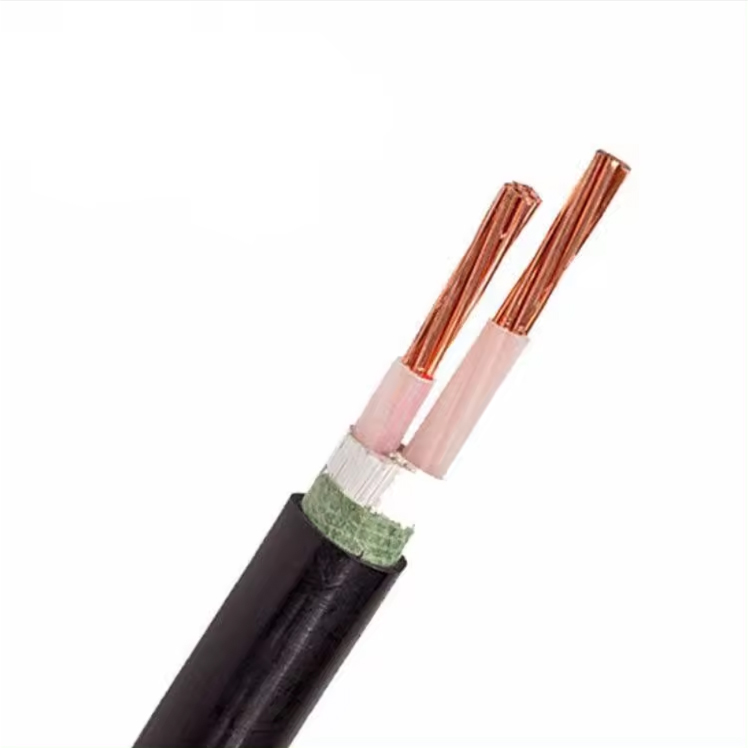

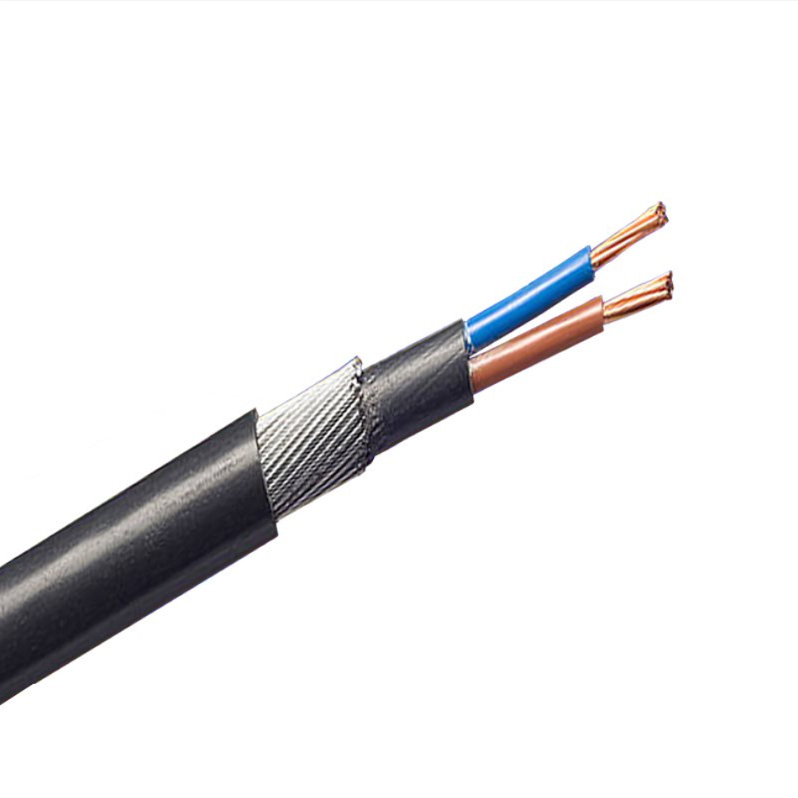

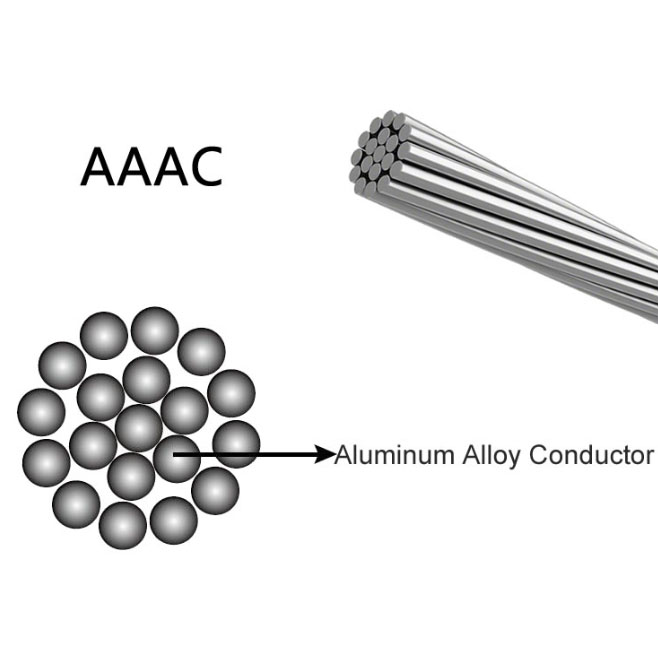

Construction

AAAC cable consists of aluminum alloy wires.

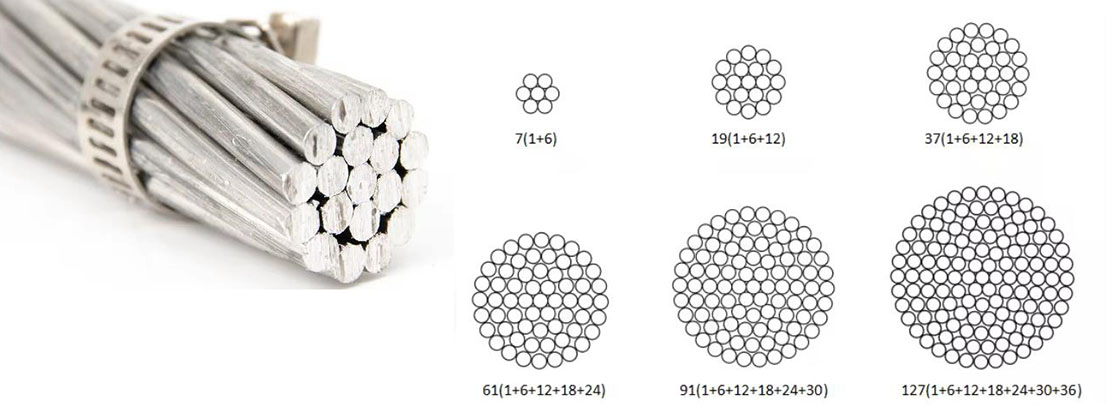

The aluminum alloy wires are concentrically lay stranded.

Aluminum Alloy Wires Strands: 7, 19, 37, 61, 91 etc.

Feature

1. Good corrosion resistanceAAAC conductors have good corrosion resistance because they consist only of aluminum alloy wires, they have better corrosion resistance than ACSR.

2. Better strength to weight ratioCompared with ACSR,AAAC can get better strength to weight ratio and provide improved electrical properties.

Electrical Properties

| Density at 20°C | 2.70 kg/dm |

| Temperature Coefficient at 20°C | 0.00360 (°C) |

| Resistivity at 20°C | 0.0326 Ohms mm2/m |

| Linear Expansivity | 23 x10-6(°C) |

Standard

BS 3242 / BS EN 50182 / IEC 61089 / ASTM B 399/B 399M / DIN 48201-6

Packing material

Wooden drum, steel-wooden drum, steel drum.

Specification

IEC 61089 Specification for Round wire concentric lay overhead electrical stranded conductors.

Specifications

| Code | Nominal Area | Stranding | Overall Diameter | Weight | Rated Strength | Electrical Resistance | Current Rating |

| mm² | No./mm | mm | kg/km | KN | Ω/KM | A | |

| 16 | 18.4 | 7/1.83 | 5.49 | 50.4 | 5.43 | 1.7896 | 86 |

| 25 | 28.8 | 7/2.29 | 6.87 | 78.7 | 8.49 | 1.1453 | 113 |

| 40 | 46 | 7/2.89 | 8.67 | 125.9 | 13.58 | 0.7158 | 151 |

| 63 | 72.5 | 7/3.63 | 10.89 | 198.3 | 21.39 | 0.4545 | 200 |

| 100 | 115 | 19/.78 | 13.9 | 316.3 | 33.95 | 0.2877 | 266 |

| 125 | 144 | 19/3.1 | 15.5 | 395.4 | 42.44 | 0.2302 | 305 |

| 160 | 184 | 19/3.51 | 17.55 | 506.1 | 54.32 | 0.1798 | 355 |

| 200 | 230 | 19/3.93 | 19.65 | 632.7 | 67.91 | 0.1439 | 407 |

| 250 | 288 | 19/4.39 | 21.95 | 790.8 | 84.88 | 0.1151 | 466 |

| 315 | 363 | 37/3.53 | 24.71 | 998.9 | 106.95 | 0.0916 | 535 |

| 400 | 460 | 37/3.98 | 27.86 | 1268.4 | 135.81 | 0.0721 | 618 |

| 450 | 518 | 37/4.22 | 29.54 | 1426.9 | 152.79 | 0.0641 | 663 |

| 500 | 575 | 37/4.45 | 31.15 | 1585.5 | 169.76 | 0.0577 | 706 |

| 560 | 645 | 61/3.67 | 33.03 | 1778.4 | 190.14 | 0.0516 | 755 |

| 630 | 725 | 61/3.89 | 35.01 | 2000.7 | 213.9 | 0.0458 | 809 |

| 710 | 817 | 61/4.13 | 37.17 | 2254.8 | 241.07 | 0.0407 | 866 |

| 800 | 921 | 61/4.38 | 39.42 | 2540.6 | 271.62 | 0.0361 | 928 |

| 900* | 1036 | 91/3.81 | 41.91 | 2861.1 | 305.58 | 0.0321 | 992 |

| 1000* | 1151 | 91/4.01 | 44.11 | 3179 | 339.53 | 0.0289 | 1051 |

| 1120* | 1289 | 91/4.25 | 46.75 | 3560.5 | 380.27 | 0.0258 | 1118 |

| 1250* | 1439 | 91/4.49 | 49.39 | 3973.7 | 424.41 | 0.0231 | 1185 |

Note: The values of current rating mentioned in above Table are based on wind velocity of 0.6 metre/second, solar heat radiation of 1200 watt/metre2, ambient temperature of 50°C & conductor temperature of 80°C.